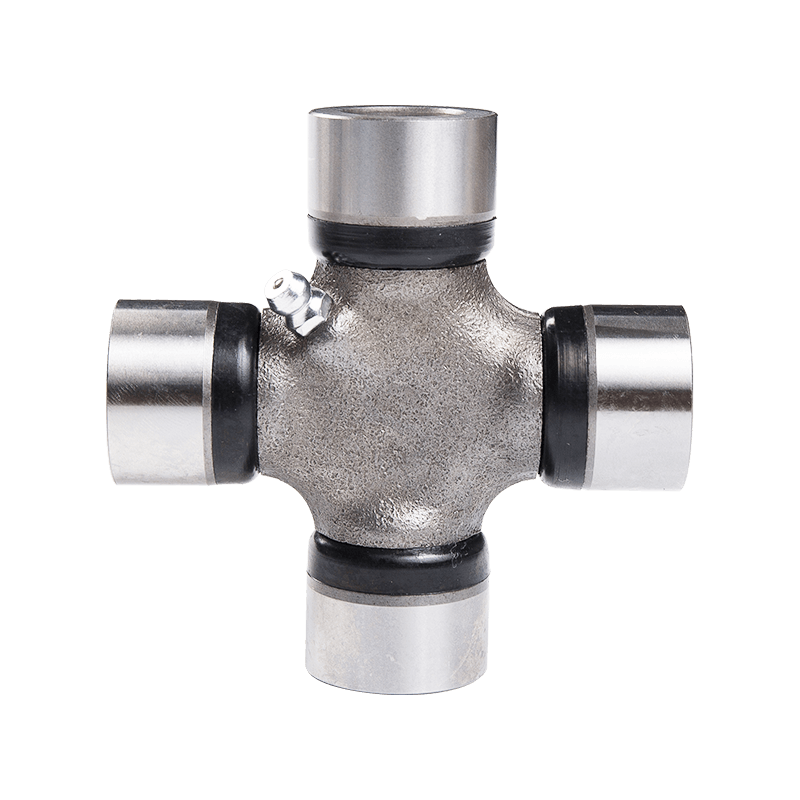

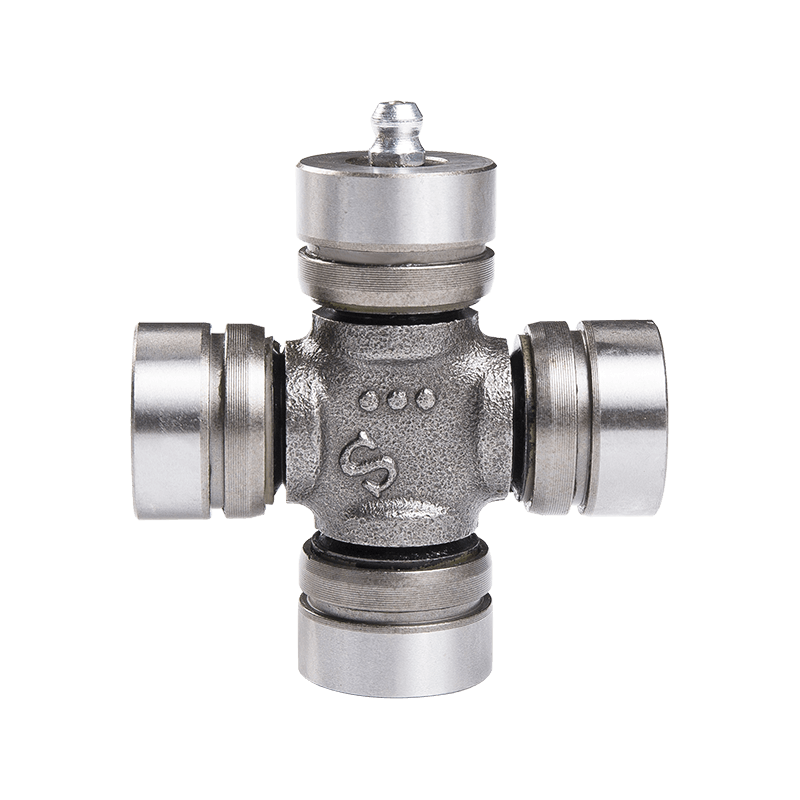

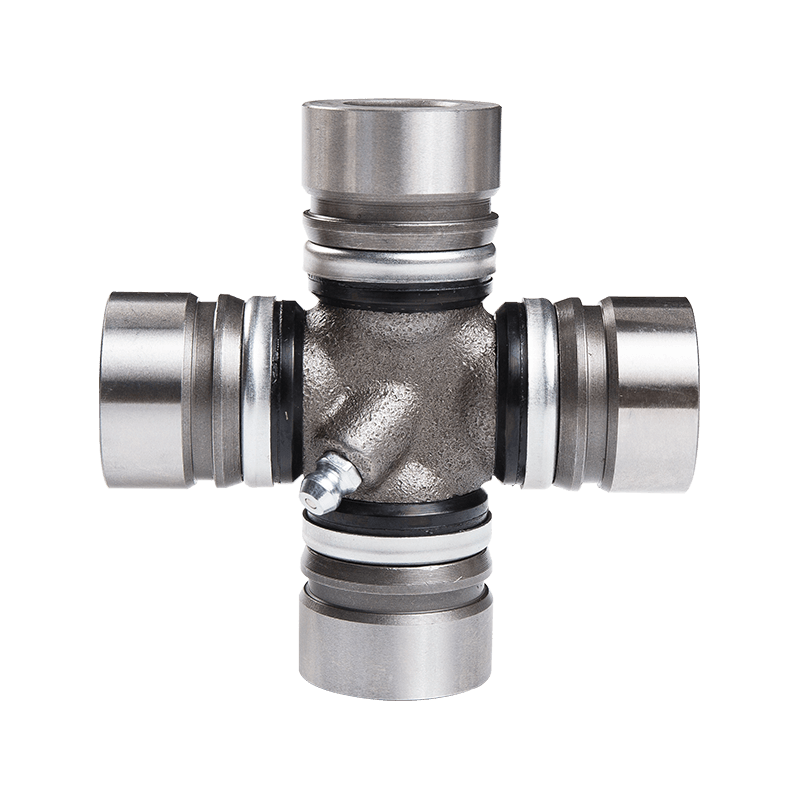

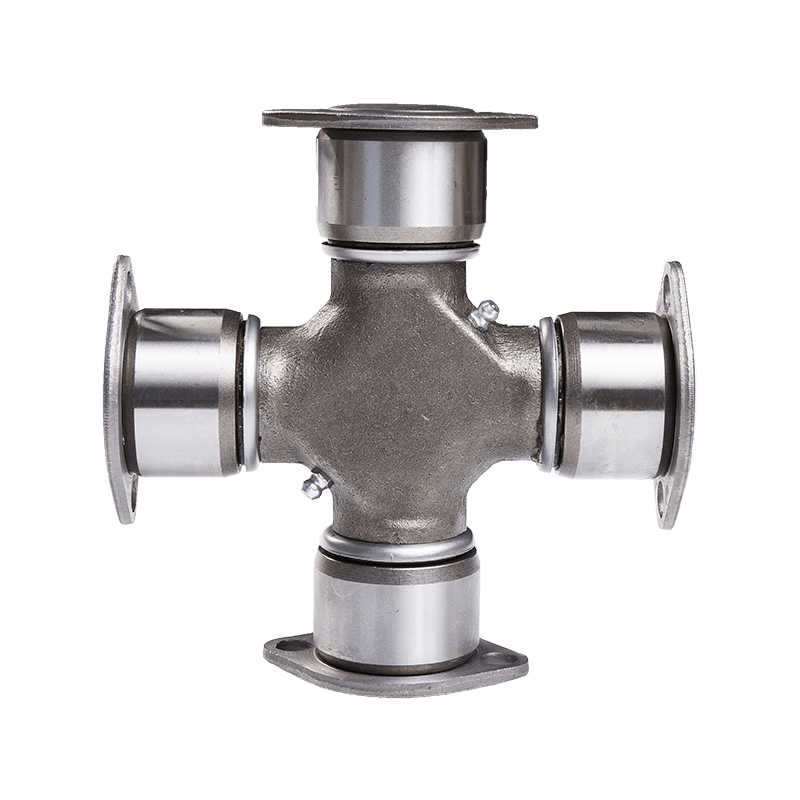

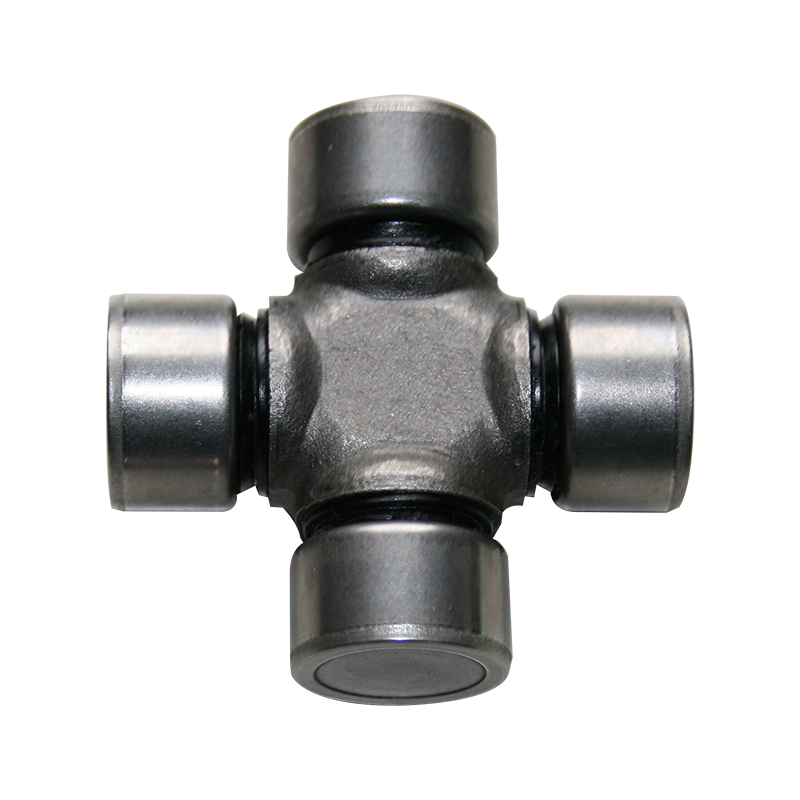

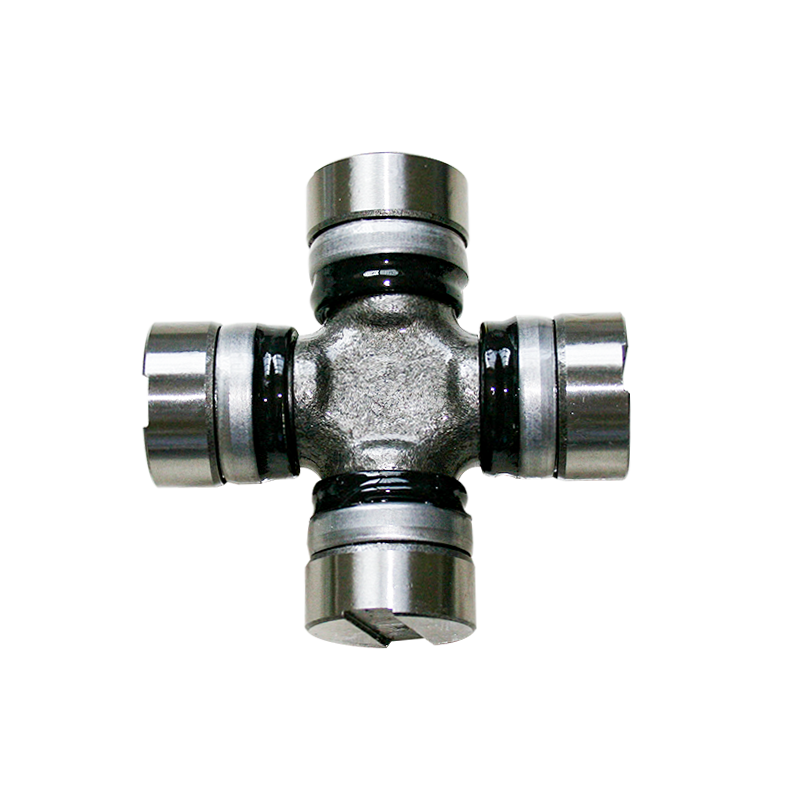

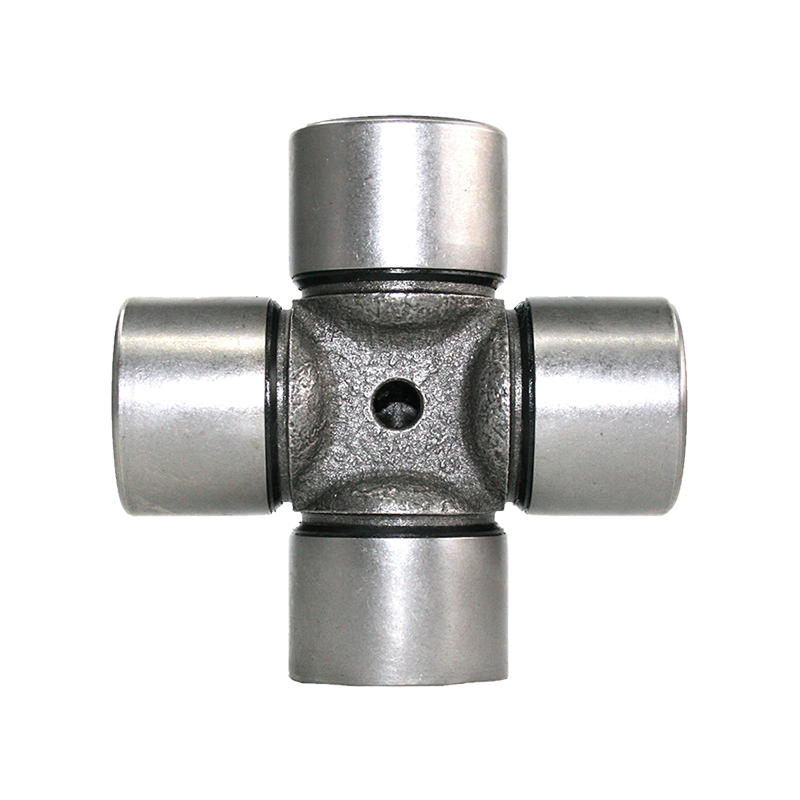

Universal joints, commonly referred to as U-joints or cardan joints, are essential components in mechanical systems that facilitate the transmission of motion and power between shafts at angles. Their ability to accommodate misalignment makes them invaluable in a variety of applications, especially in automotive and industrial machinery. A specific type of universal joint, the one featuring an inside snap ring, enhances reliability by securely locking the cup in place, preventing dislocation during operation. This design not only simplifies installation but also improves the joint's overall integrity, which is critical for maintaining performance under stress.

When it comes to the maintenance and longevity of universal joints with inside snap rings, a common question arises: can these joints be repaired, or do they need to be replaced when they show signs of wear or damage? The answer depends on several factors, including the extent of the damage, the type of failure, and the specific application in which the joint is used. In some cases, minor issues such as insufficient lubrication or early signs of wear may be addressed through routine maintenance, which can extend the life of the joint. Regular inspections can help identify these early warning signs, allowing for lubrication or adjustment before significant damage occurs.

However, if the damage is more severe—such as cracks in the cup, excessive play, or significant wear on the bearings—replacement is typically the most prudent option. The structural integrity of the joint is paramount, and attempting to repair a severely damaged U-joint could compromise performance, leading to potential failure during operation. Moreover, replacement parts are widely available, and advancements in manufacturing have improved the durability and efficiency of these components. Thus, investing in a new universal joint can often be more cost-effective and safer than attempting to salvage a compromised one.

The decision to repair or replace also involves considering the specific application and operating conditions. For instance, in high-performance settings such as racing or heavy-duty machinery, the demands on the universal joint are significantly greater, making reliable function critical. In these scenarios, opting for a replacement rather than risking a repair can ensure consistent performance and safety. Additionally, modern universal joints, particularly those with features like inside snap rings, are engineered to be more resilient and often come with warranties, providing peace of mind regarding their durability.

While some minor issues with universal joints with inside snap rings can potentially be addressed through maintenance and minor repairs, significant damage typically necessitates replacement. Regular inspections and adherence to maintenance protocols can help prolong the life of these vital components, but understanding when to replace them is crucial for ensuring the safety and reliability of the machinery they serve. Ultimately, the goal is to maintain optimal performance, and in many cases, investing in a new universal joint is the best course of action for achieving that.

English

English Español

Español 中文简体

中文简体

Contact Us