A

Universal Joint cross operates by transferring torque between intersecting shafts that are not in a straight line or not in perfect alignment. This functionality is crucial in mechanical systems where two shafts need to transfer rotational power, even if they are set at varying angles to each other. The operation involves a few key principles:

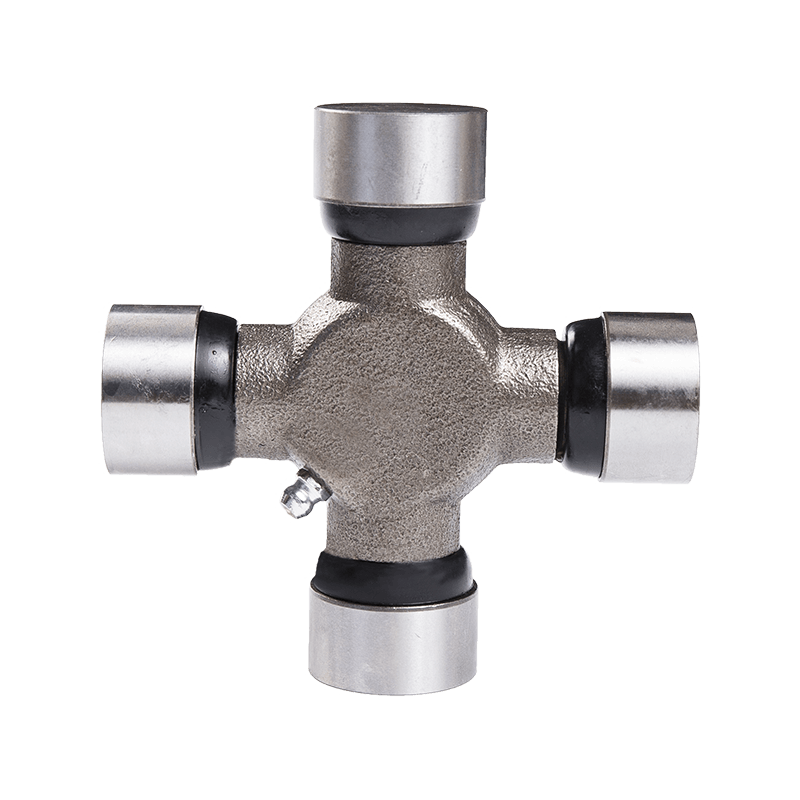

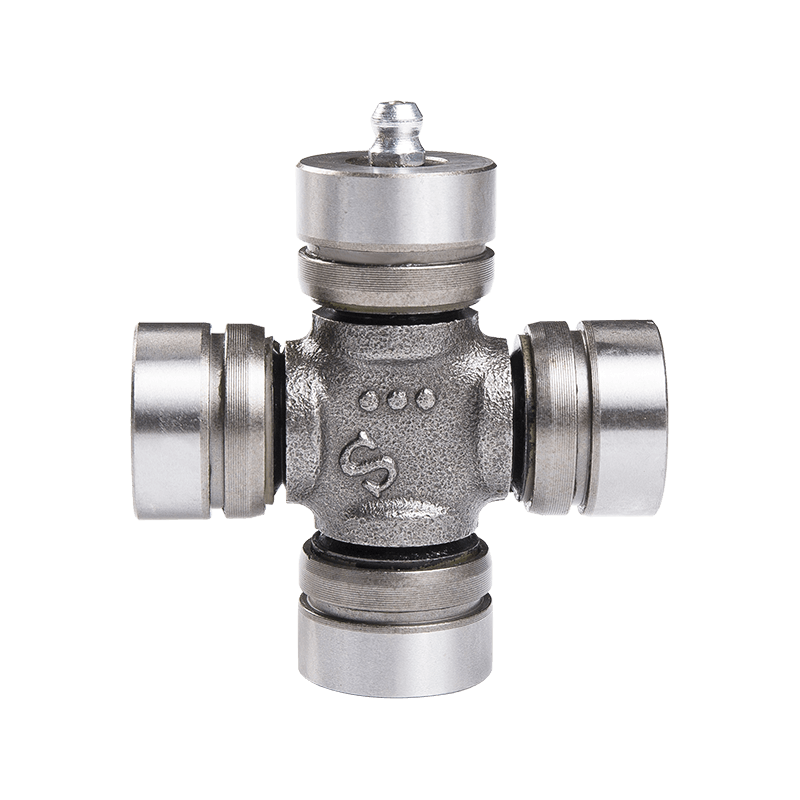

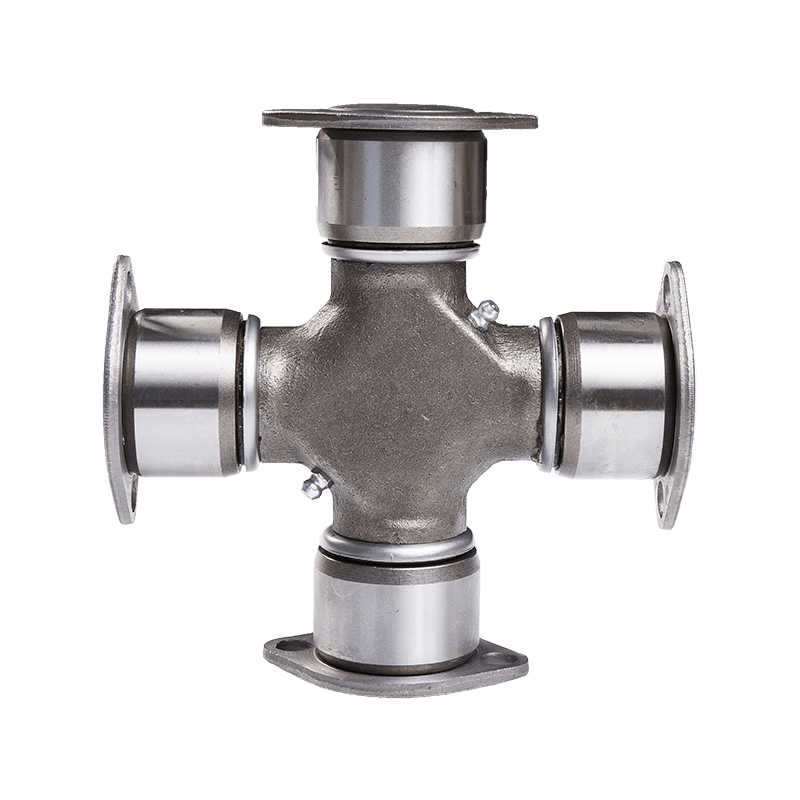

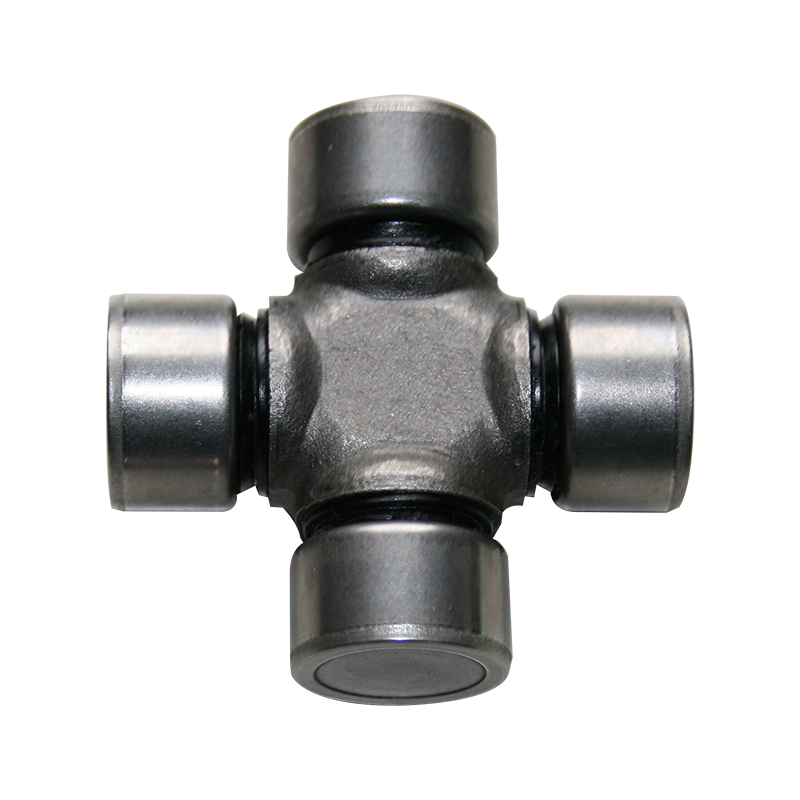

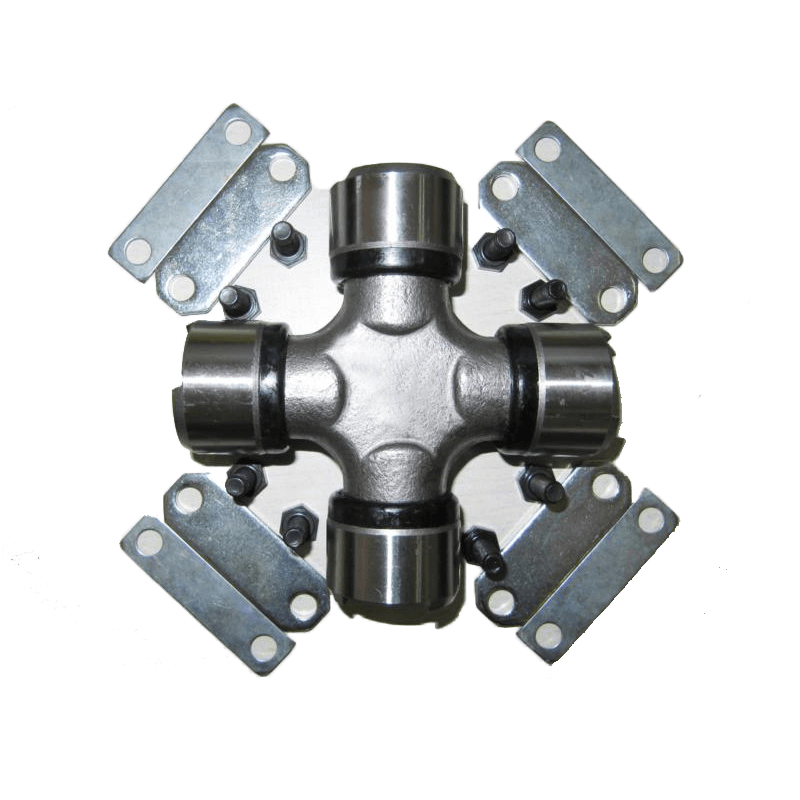

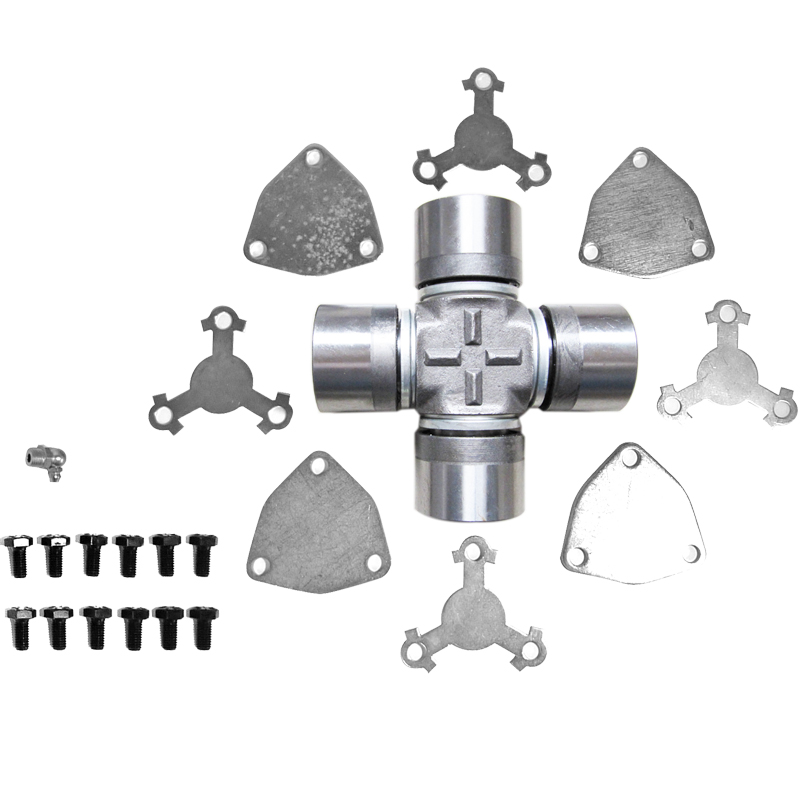

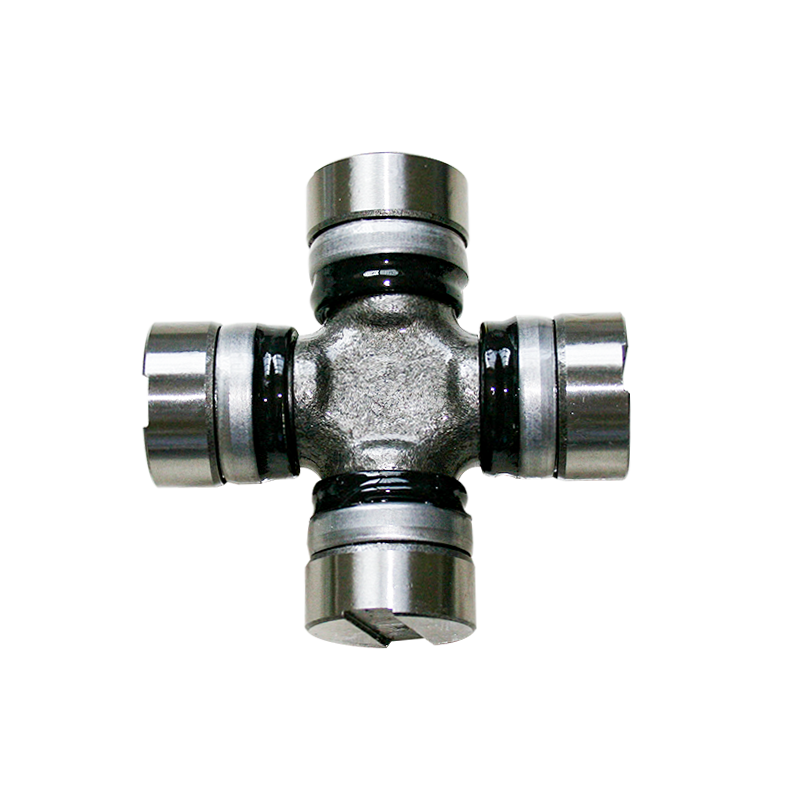

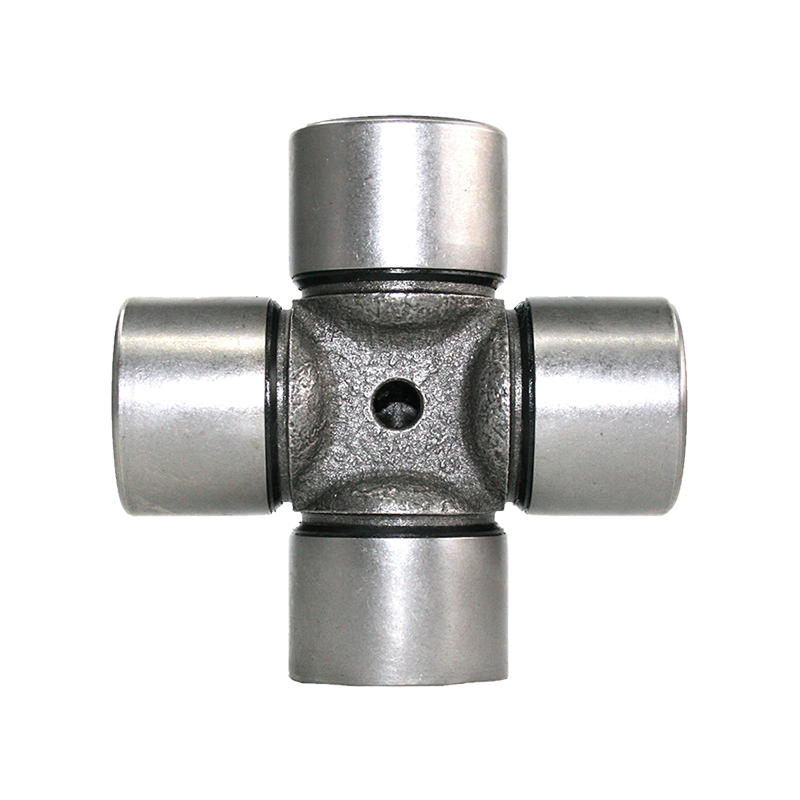

Flexibility: The U-joint cross is constructed in a cross-shaped design, connecting two shafts at angles. The four arms of the cross are fitted onto the shafts, allowing for flexibility.

Bearings or Bushings: Each arm of the U-joint typically has bearings or bushings at its ends. These connect to bearing caps or cups, allowing for smooth rotation and reducing friction during operation.

Angular Movement Accommodation: When one shaft rotates, the U-joint cross, due to its design, allows for angular movement between the connected shafts. This flexibility permits torque to be transmitted even when the shafts are not perfectly aligned.

Torque Transmission: As one shaft turns, it causes a rotational force to act upon the U-joint. This force is transmitted through the

Universal Joint cross to the other shaft, even if they're at different angles, allowing the torque to be transferred across axes.

Compensating for Misalignment: The U-joint compensates for angular misalignment between shafts by flexing and rotating. This helps transmit torque despite the varying angles between the connected shafts.

Regular Maintenance: Adequate lubrication and regular maintenance of the U-joint's bearings or bushings are essential to minimize wear and maintain smooth operation. Neglecting proper maintenance can lead to premature failure of the U-joint.

English

English Español

Español 中文简体

中文简体

Contact Us