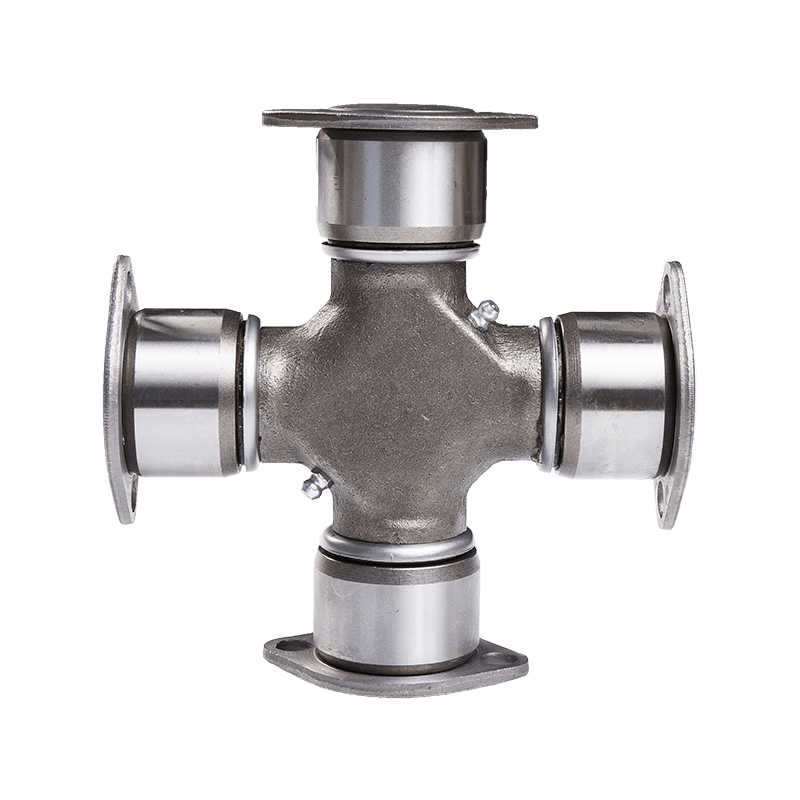

How does Universal Joint With Weld Plate Bearings 5-281X For SPICER 1810 Series deal with alignment and misalignment issues between shafts connected by a universal joint?

Universal Joints with Weld Plate Bearings are designed to address alignment and misalignment issues between connected shafts by offering flexibility and articulation. Here’s how they handle these issues:

Flexibility in Movement: Weld plate bearings within the joint assembly provide a degree of flexibility. They can compensate for minor misalignments between shafts while maintaining the transfer of torque.

Tolerance for Misalignment: These bearings can tolerate a certain amount of misalignment, allowing the shafts to function effectively even when they are not perfectly aligned.

Movable Connection: The weld plate bearings within the joint offer a movable connection, allowing the shafts to adjust their positions within certain limits, accommodating misalignments while preserving torque transmission.

Stress Reduction on Components: The design of the weld plate bearings aims to minimize stress on the joint's components by allowing for misalignment without subjecting the parts to excessive strain.

Torque Transmission Maintenance: Even with misalignment, the weld plate bearings ensure that torque transfer between the connected shafts remains relatively consistent.

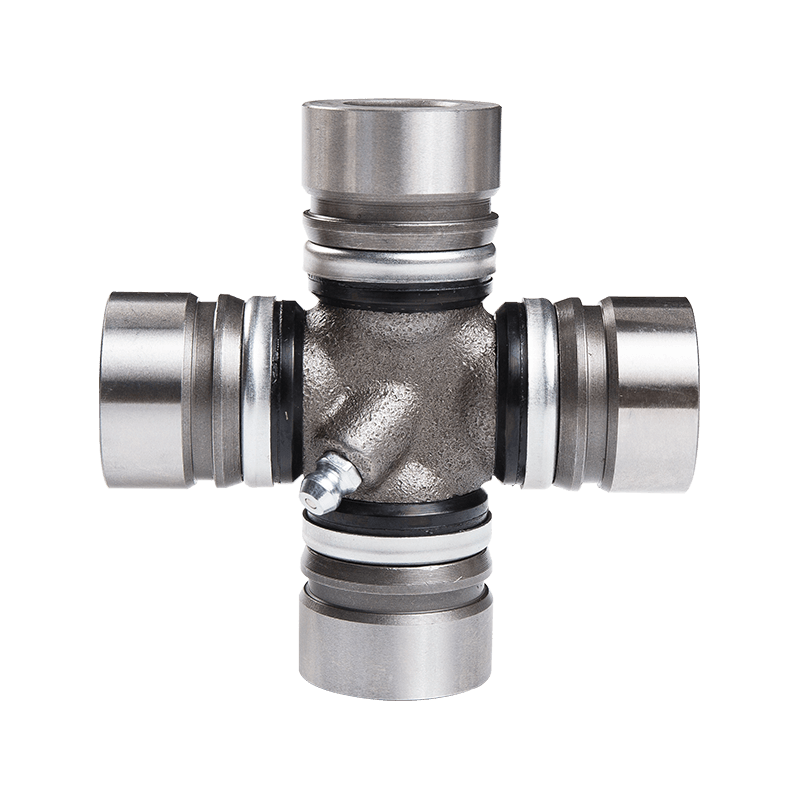

What are the load or torque specifications of Universal Joint With Weld Plate Bearings 5-281X For SPICER 1810 Series?

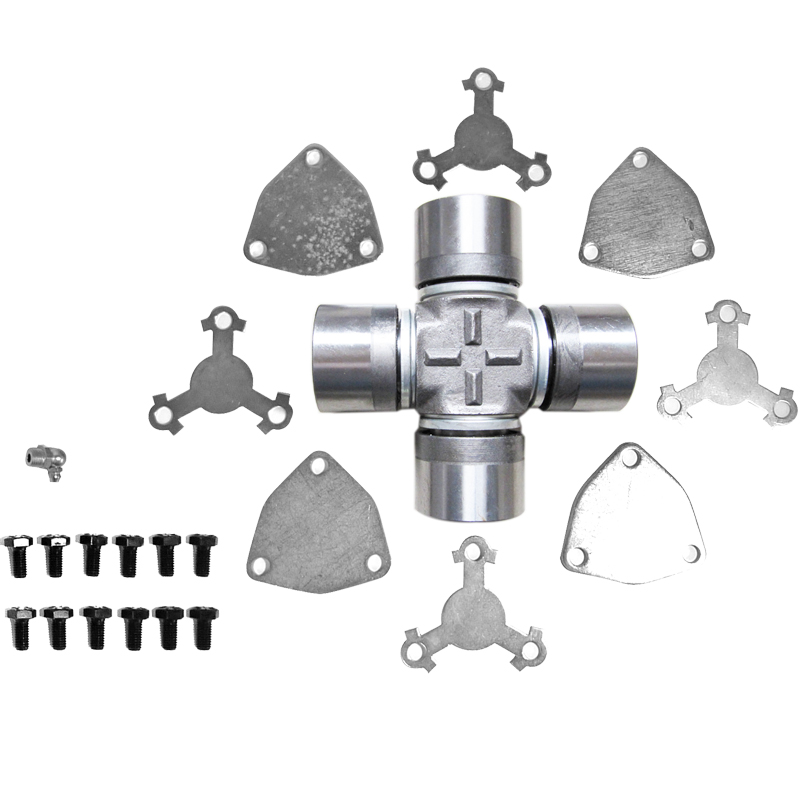

The specific load or torque specifications of a Universal Joint With Weld Plate Bearings 5-281X For SPICER 1810 Series can vary significantly based on factors such as the design, materials, size, and intended application. These specifications are typically determined by the manufacturer and are specific to each model or variant of the universal joint.

Design and Size: The design and size of the weld plate bearings, as well as the entire joint assembly, significantly affect its load-bearing capacity and torque handling capabilities.

Material Selection: The choice of materials used in constructing the weld plate bearings plays a crucial role. Materials with higher tensile strength, such as specific grades of steel or alloys, can allow the joint to handle higher loads and torques.

Manufacturing Quality: Precision in manufacturing processes, including quality control measures and tolerances, directly impacts the joint's load-bearing and torque transmission abilities.

Intended Application: The load and torque specifications are influenced by the specific application and the expected workload the joint is designed to handle. A joint designed for heavy-duty industrial use will have different specifications compared to one meant for light-duty applications.

Environmental Conditions: Environmental factors, including temperature, vibration, speed, and exposure to contaminants, can also affect the load and torque specifications. The joint's ability to resist wear, corrosion, and other environmental stresses is essential.

English

English Español

Español 中文简体

中文简体