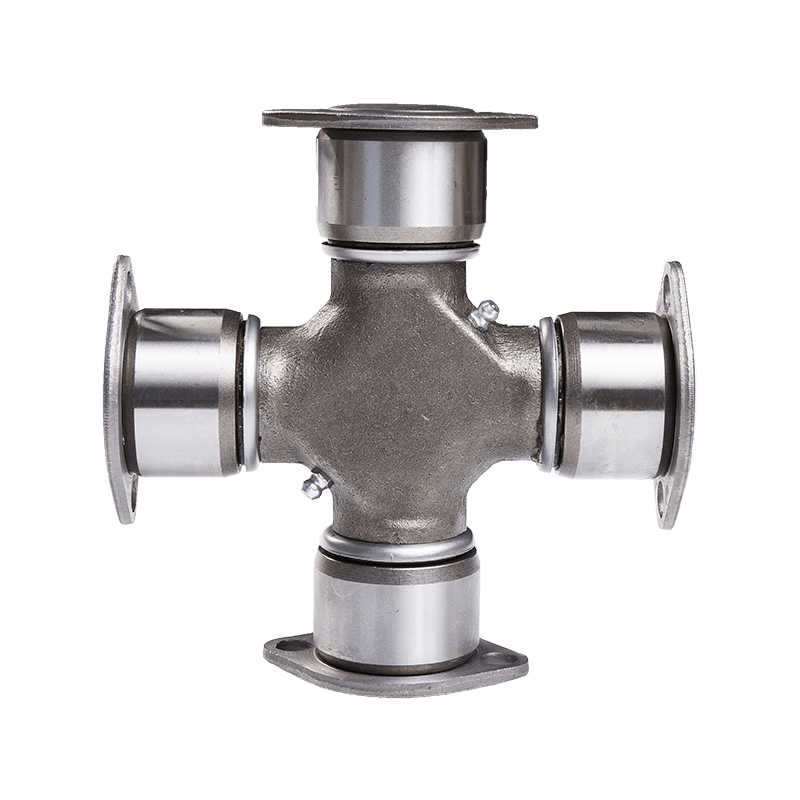

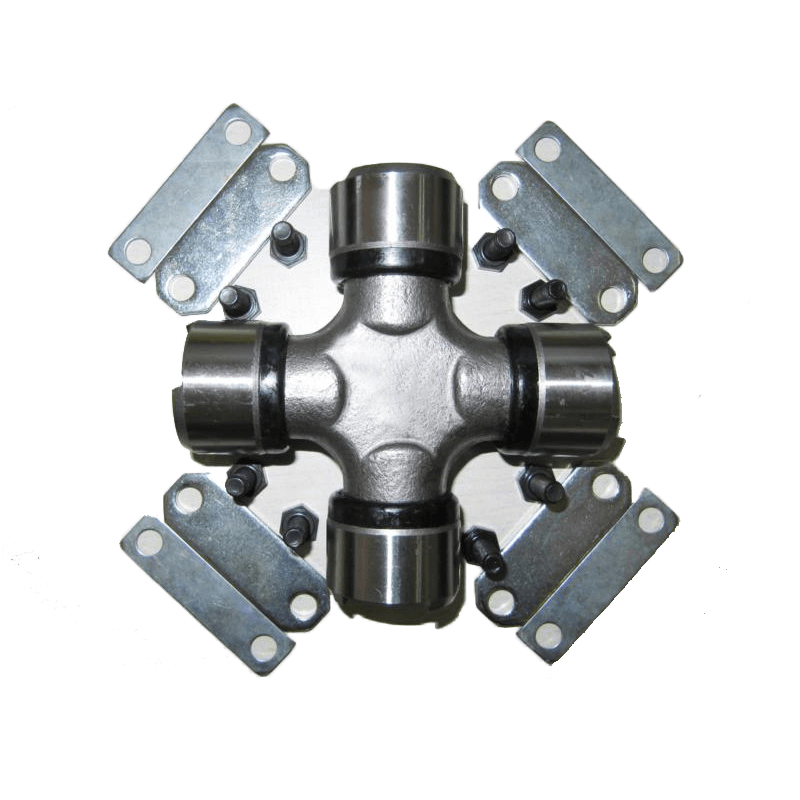

The lifespan of a universal joint in heavy-duty applications is often determined by how well it can withstand variations in load and shock forces. This is where the wing bearing design truly shines. Unlike conventional u-joints, which rely on straightforward bearing structures, the wing bearing system introduces a unique approach that significantly improves durability under challenging conditions. By distributing the torque across mechanical allowances with the help of keys positioned on the bearing blocks, the system ensures that the universal joint remains robust even under constant stress or sudden shocks. The key-to-slot connection between the bearing blocks and the fitting yokes minimizes the impact of mechanical wear, which is a common issue in more traditional joint designs.

When subjected to high-shock or continuously varying loads, universal joints without wing bearings can often experience premature wear, reduced efficiency, and even failure. The wing bearing’s ability to handle these conditions arises from its design, which accommodates slight misalignments and flexing without compromising the integrity of the joint. This flexibility prevents metal fatigue and reduces the likelihood of joint fractures, which are often a result of rigid, less adaptable systems. It’s this adaptability that significantly extends the operational life of the universal joint, making it ideal for applications in industries like automotive, heavy machinery, and even some aerospace settings.

The wing bearing design also helps to mitigate vibrations and noise, which are frequent by-products of load fluctuations in mechanical systems. By smoothing out these irregularities, the system not only improves performance but also protects other components connected to the driveshaft, ensuring that the entire system remains functional and efficient over time. In environments where the equipment is under constant load or shock, such as conveyor systems, mining machinery, or even marine applications, the wing bearing technology can be a game-changer, helping businesses avoid costly downtime and extensive repairs.

The wing bearing design is more than just a novel approach to torque transmission. It is a critical feature that enhances the durability, reliability, and performance of the universal joint, ensuring that it stands up to the toughest conditions. Whether dealing with high shock loads or continuous torque fluctuations, this advanced design offers a robust solution that extends the service life of the joint, making it a smart investment for industries demanding high-performance mechanical components.

English

English Español

Español 中文简体

中文简体

Contact Us