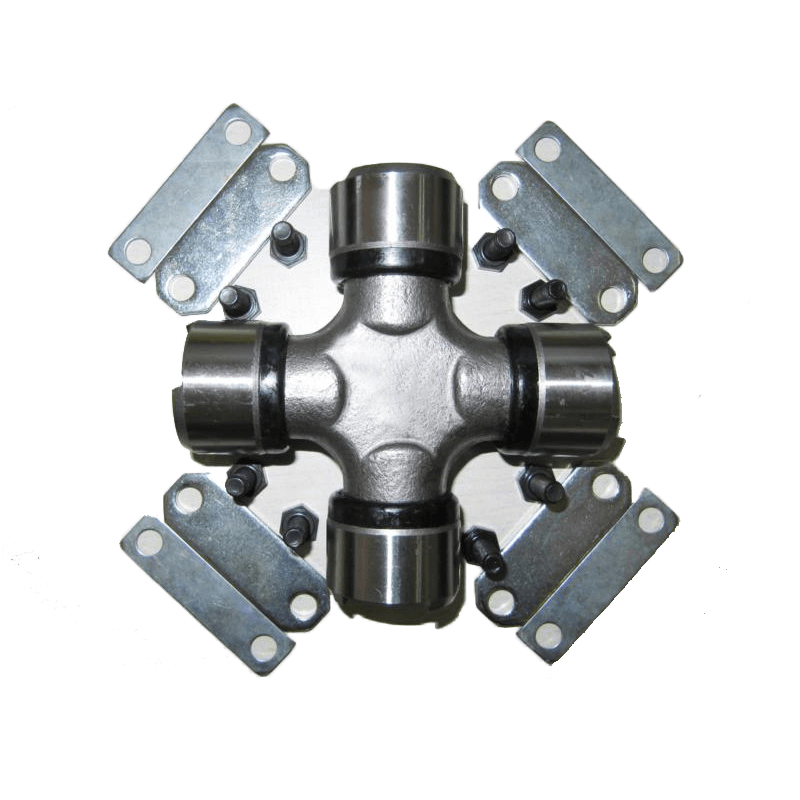

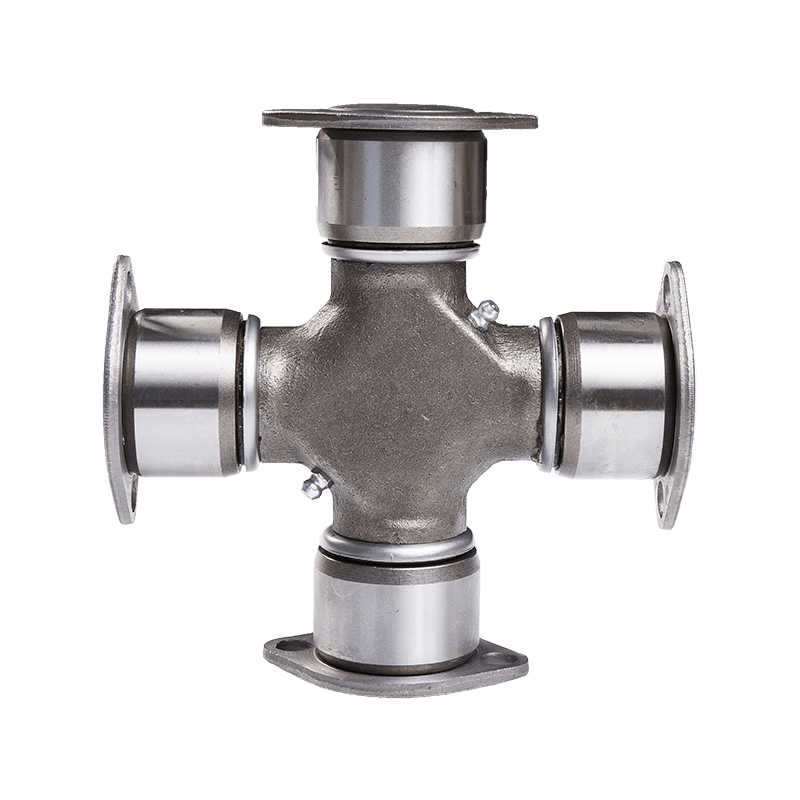

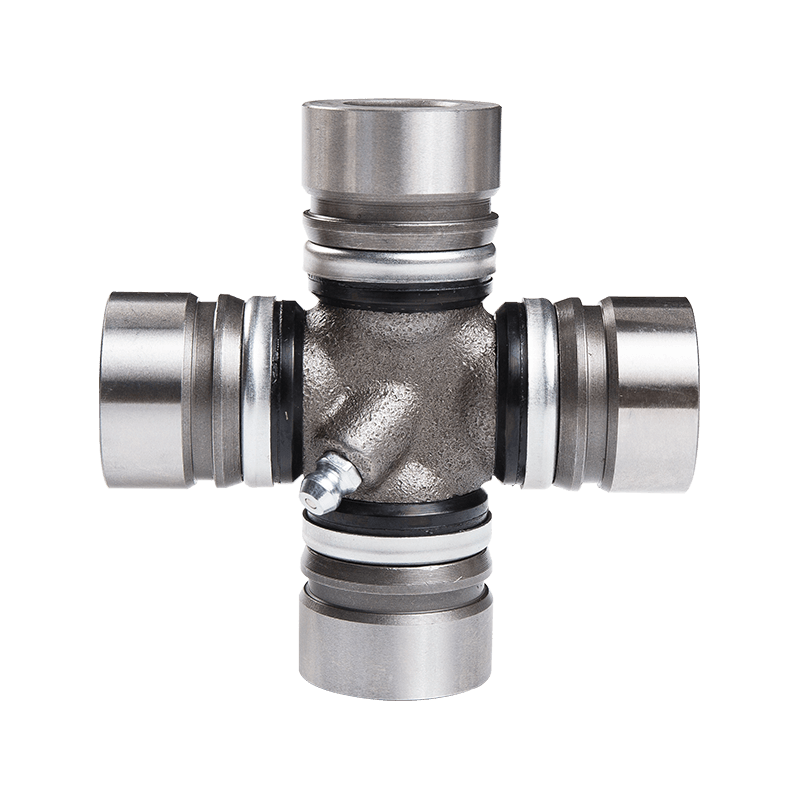

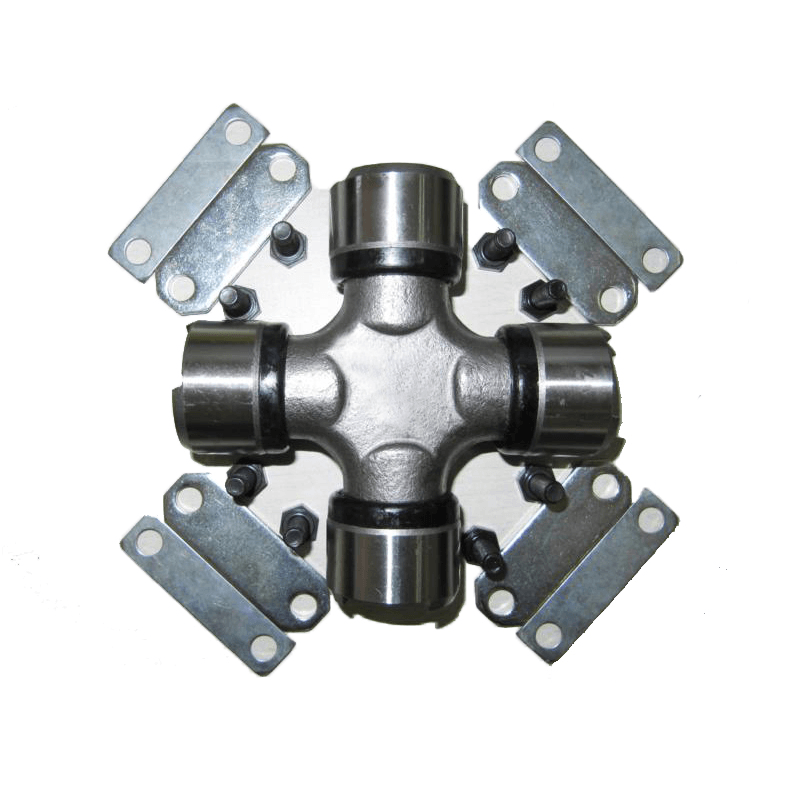

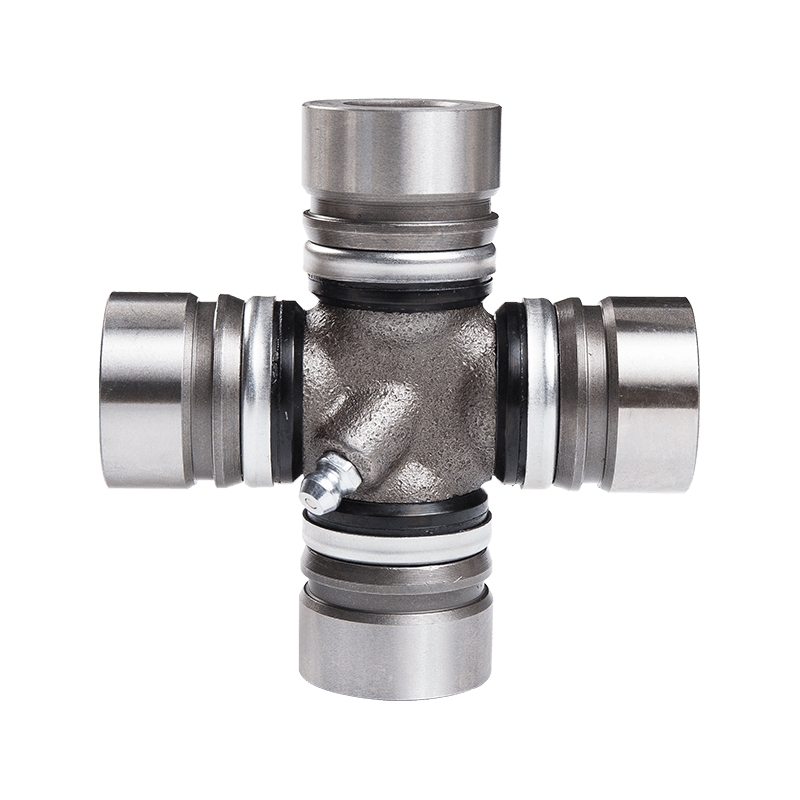

When considering the performance of universal joints with wing bearings in extreme temperature conditions, it’s important to look at the materials and design features that make them so versatile in both high heat and sub-zero environments. Wing bearings, designed with precision and built to endure constant stress and shock loads, perform exceptionally well in demanding situations, especially when extreme temperatures come into play. The unique construction of these U-joints, with their key and slot interlock design, allows them to absorb and handle temperature fluctuations that can cause more traditional U-joints to wear out faster or fail prematurely.

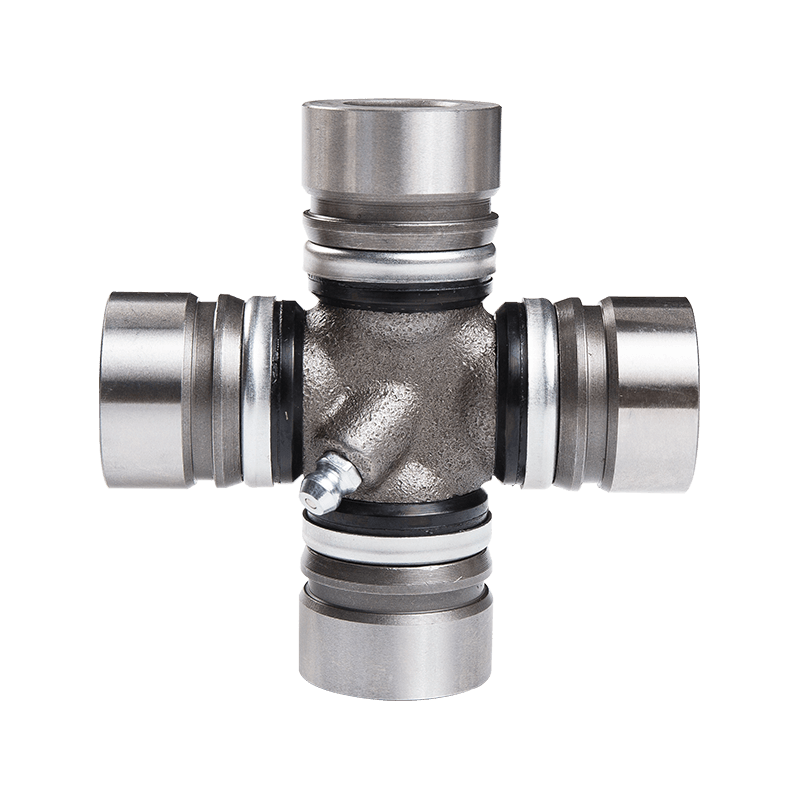

In high-heat applications, such as those found in heavy machinery operating in hot climates or industrial settings with high-temperature processes, the wing bearing U-joint’s robust construction is a key factor in its success. The materials used in both the bearings and the keys—often high-strength steel alloys—are selected for their ability to resist thermal expansion, oxidation, and material fatigue. Unlike other joints that can become brittle or degrade under heat, the wing bearings maintain their integrity, ensuring continued smooth operation. Their design also minimizes the friction between moving parts, reducing the risk of overheating even under continuous load variations or when subjected to shock loads.

On the flip side, when temperatures drop drastically, such as in cold-storage facilities, arctic environments, or other sub-zero conditions, the performance of a U-joint can be more easily compromised. However, wing bearing U-joints are specifically designed with this in mind. The precision fit of the keys and slots helps to maintain an efficient transfer of torque, even when the metal components contract in cold weather. The materials used for the bearings are also less likely to suffer from brittleness at low temperatures, thanks to their inherent toughness and resistance to cracking or breaking under stress. Whether it’s -40°C or below, these universal joints remain reliable and functional, crucial for industries that operate in extreme cold.

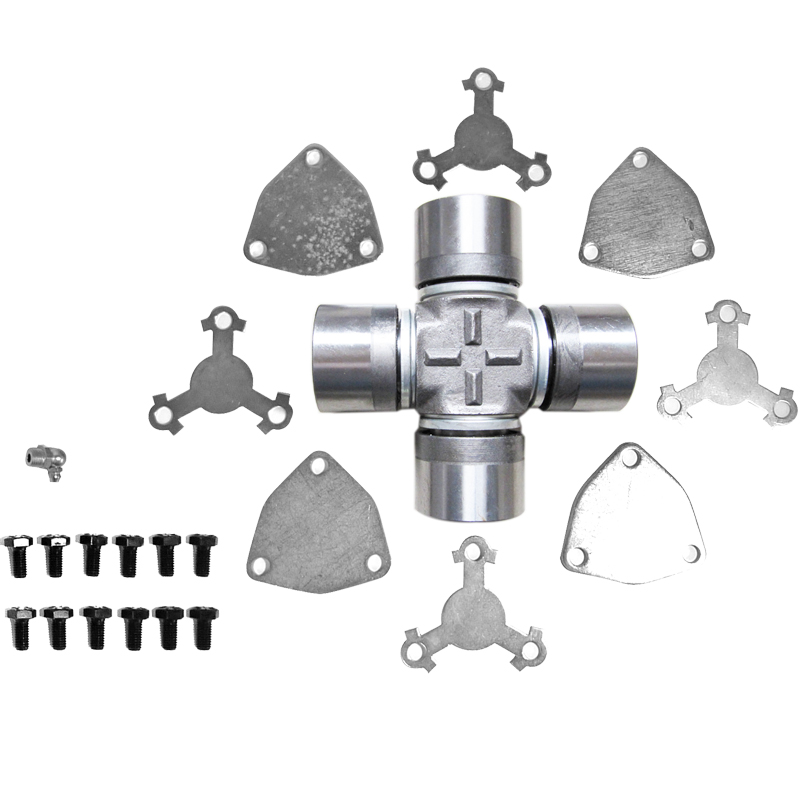

What makes these universal joints even more appealing for tough environments is their design for ease of maintenance. Because they are assembled with bolts, they can be disassembled and serviced with relative ease, reducing downtime and making repairs quicker when necessary. This is a significant advantage for operations in extreme temperatures, where minimizing maintenance time is critical. Additionally, because these parts are designed to absorb shock loads, they can handle sudden temperature shifts that might otherwise lead to mechanical failures in more fragile joints.

The wing bearing U-joints provide a perfect balance of performance, durability, and adaptability in extreme temperatures. Their specialized design makes them an excellent choice for industries operating in harsh environments, whether dealing with the intense heat of an industrial furnace or the chilling cold of high-altitude construction sites. With these U-joints, the challenges posed by extreme temperatures can be tackled with confidence, ensuring that machinery continues to perform at its best.

English

English Español

Español 中文简体

中文简体

Contact Us