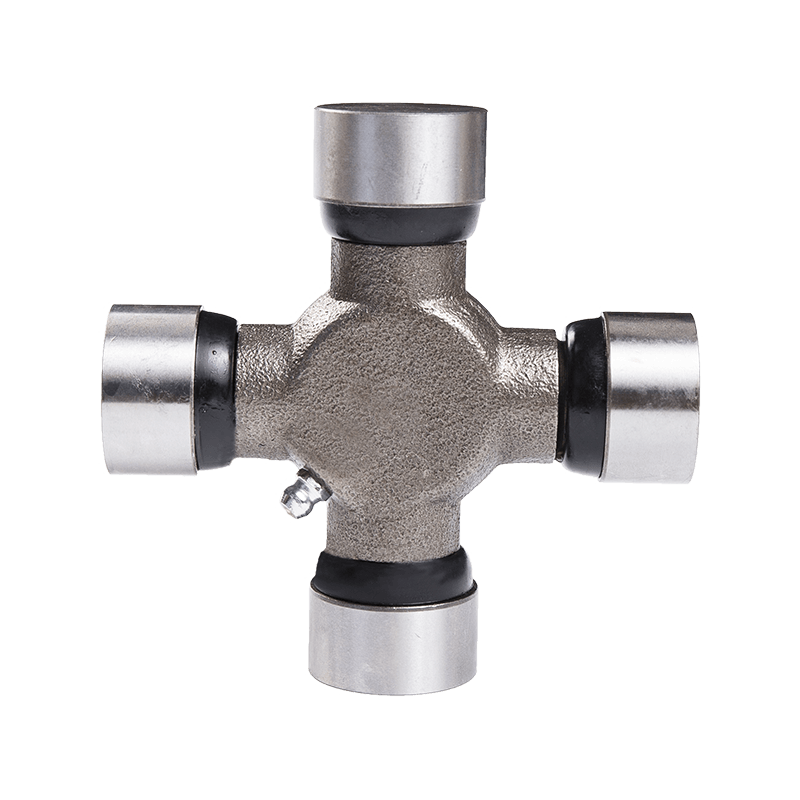

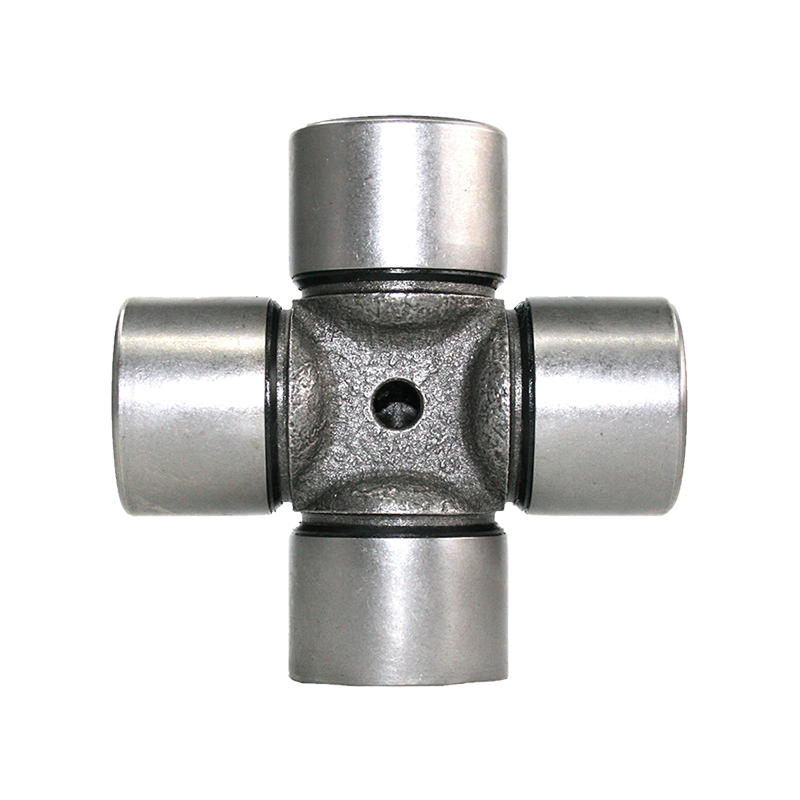

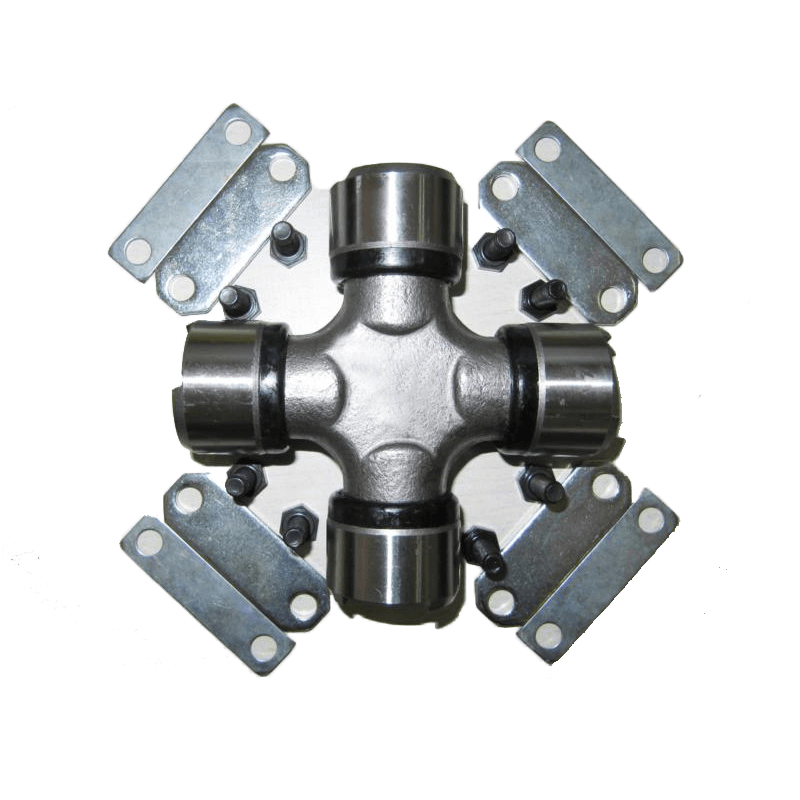

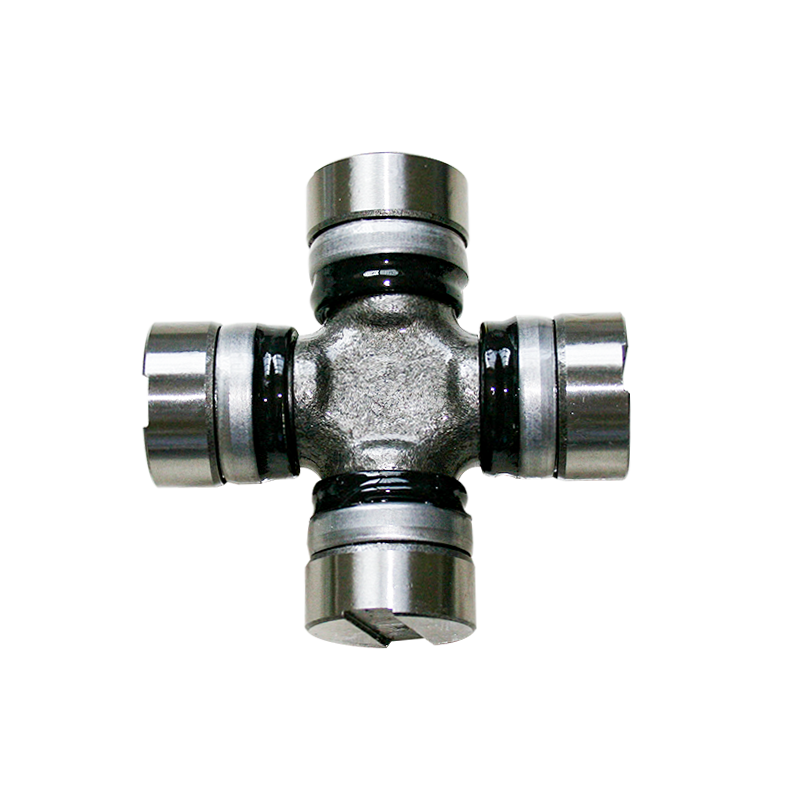

Universal joints with pressed bearings represent a significant advancement over those using traditional bearings, offering several key advantages that make them ideal for high-performance applications. At the heart of these improvements is the use of specialized materials and engineering techniques that enhance both durability and efficiency.

One of the primary advantages of pressed bearings in universal joints is their ability to support higher performance levels while maintaining a more compact design. Pressed bearings are crafted from advanced materials that allow for a thinner cup body compared to traditional bearings. This reduction in size and weight does not compromise the joint's strength or functionality; instead, it contributes to a more streamlined and lighter component. The lighter design helps reduce the overall weight of the drive shaft assembly, which can lead to better fuel efficiency and performance in applications where weight is a critical factor, such as in high-performance vehicles or machinery.

Additionally, pressed bearings are engineered to offer superior durability and reduced friction. The specialized materials used in these bearings are designed to withstand extreme stresses and high temperatures, which are common in high-performance environments. This resilience translates to longer service life and enhanced reliability, reducing the frequency of maintenance and replacements. The decreased friction associated with pressed bearings also results in smoother operation and less wear on surrounding components, further contributing to the overall efficiency and longevity of the drive shaft system.

In comparison, traditional bearings often require a larger cup body to achieve similar performance levels, which can increase the weight and size of the universal joint. This design can limit the overall efficiency and handling characteristics of the vehicle or machinery. Traditional bearings might also face higher friction and wear rates under demanding conditions, leading to more frequent maintenance and potential performance issues.

The use of pressed bearings in universal joints, such as those featured in high-quality products, exemplifies these advantages by providing a blend of reduced weight, increased durability, and improved performance. For example, products like those from reputable brands offer enhanced performance attributes, making them suitable for premium drive shafts where precision and reliability are paramount. The combination of advanced materials and engineering in these Universal joints with pressed bearings ensures that they not only meet but exceed the demands of modern high-performance applications.

The transition to pressed bearings in universal joints represents a notable advancement in engineering and material science, providing benefits such as reduced weight, greater durability, and smoother operation. These improvements make pressed-bearing universal joints a superior choice for applications requiring high performance and reliability, setting them apart from their traditional counterparts.

English

English Español

Español 中文简体

中文简体

Contact Us