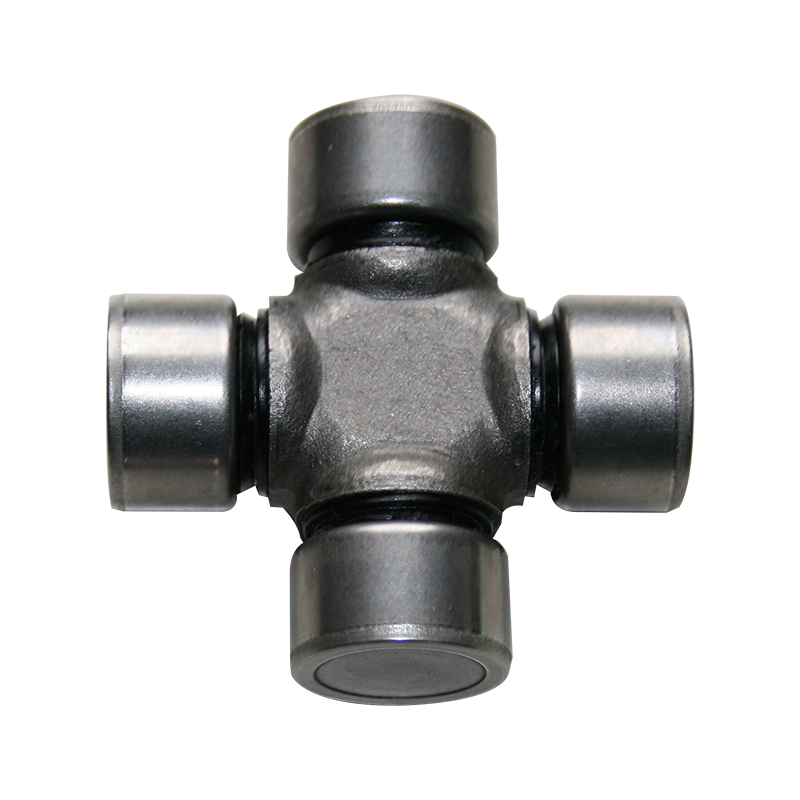

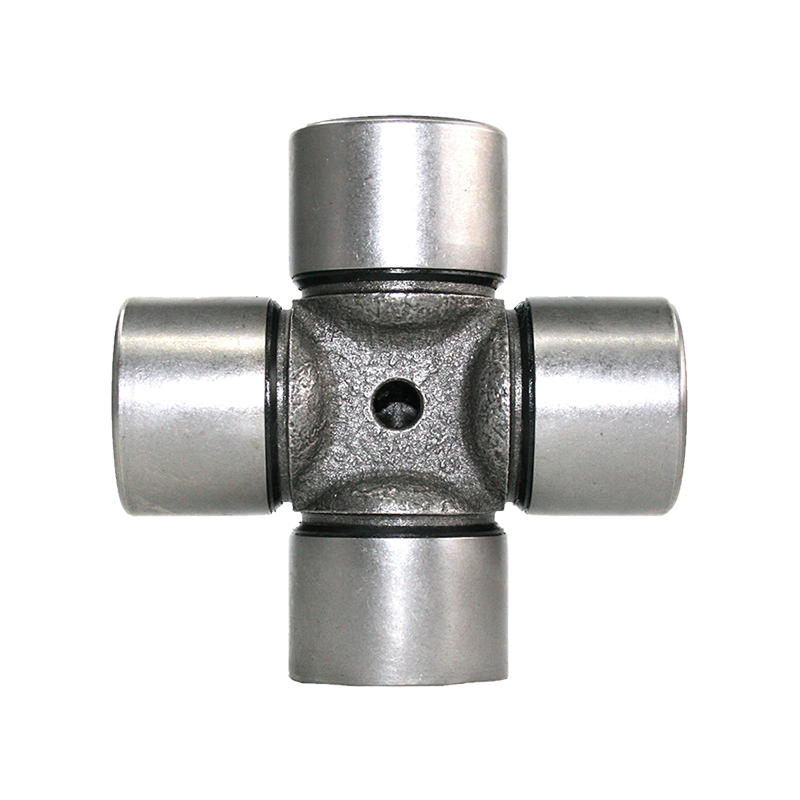

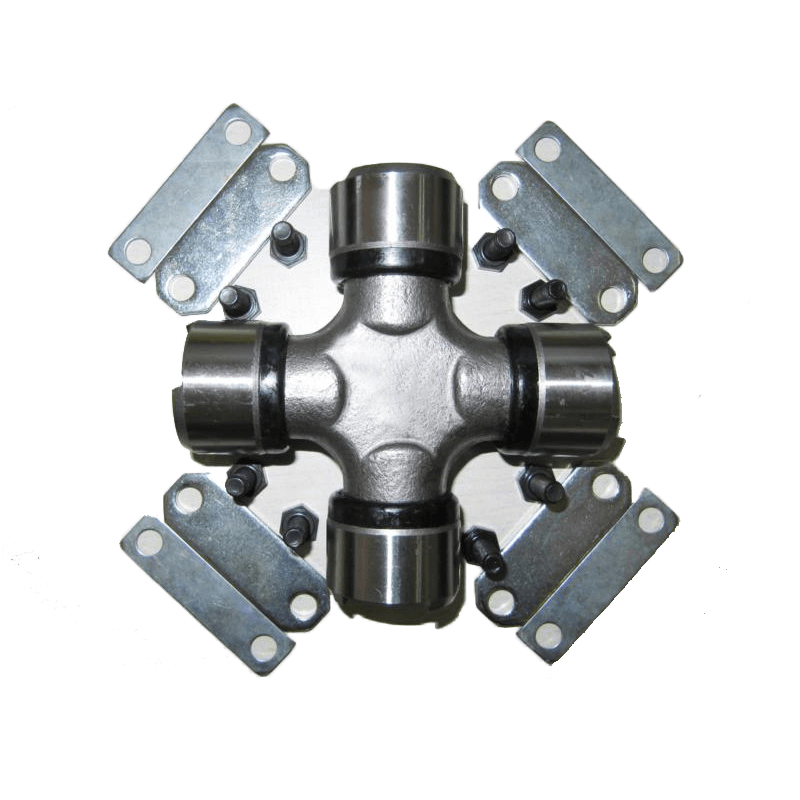

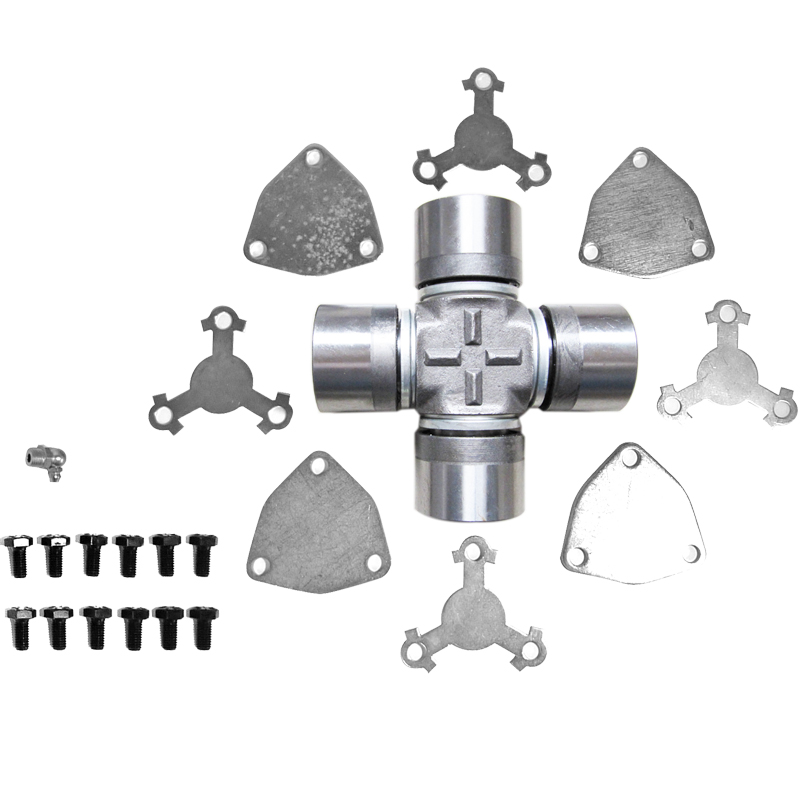

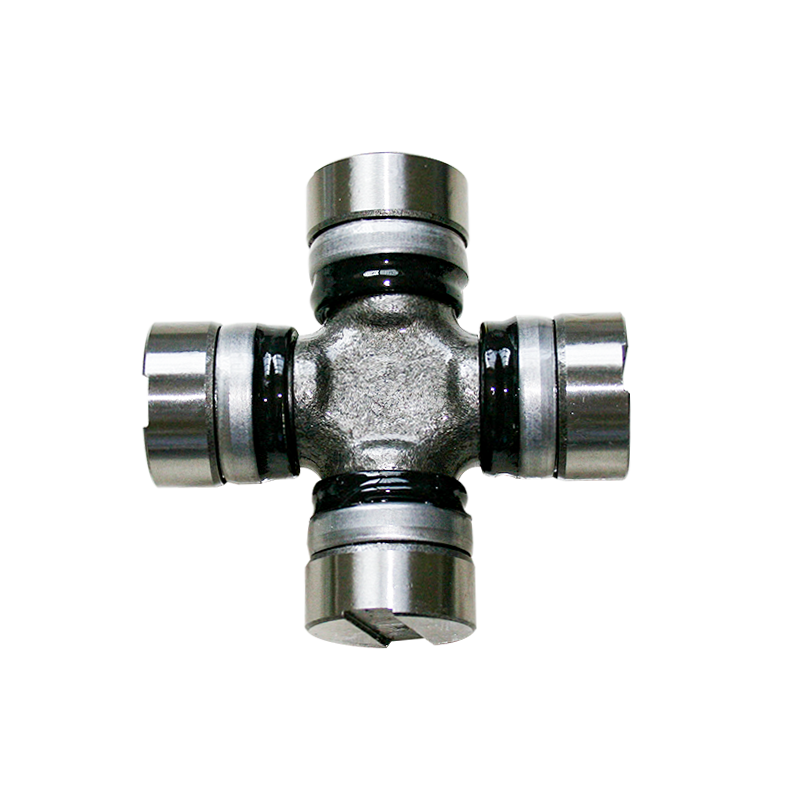

Universal joints with slotted bearings play a critical role in heavy-duty trucks, facilitating the transmission of rotational motion between shafts that are not aligned. These components are designed to withstand immense stress and torque, making them vital for the reliable operation of commercial vehicles. Unlike standard U-joints, those with slotted bearings feature a unique design that incorporates grooves on the bottom of the cup. This design allows for a secure retention mechanism using a plate and bolts, enhancing the stability and durability of the joint assembly.

One of the primary considerations for maintaining the performance and safety of heavy-duty trucks is the regular inspection and replacement of universal joints with slotted bearings. These inspections are crucial to identifying early signs of wear or damage that could lead to potential failures if left unchecked. Typically, manufacturers recommend inspecting these joints every 25,000 to 50,000 miles (40,000 to 80,000 kilometers), or every 6 months to 1 year, depending on the operating conditions and intensity of use.

During inspections, it's essential to conduct both visual and physical checks. Visual inspections involve looking for any visible signs of wear or damage, such as excessive play in the joint, unusual noises during operation, or abnormalities in the slotted bearings and their retention mechanism. Physical inspections may include measuring the amount of play in the joint and assessing the condition of the slotted groove and its components.

The operating conditions of the truck play a significant role in determining inspection intervals. Trucks that operate under severe conditions, such as off-road terrain, heavy hauling, or environments with high levels of dust or moisture, may require more frequent inspections. These harsh conditions can accelerate wear on the universal joints, necessitating closer monitoring and potentially shorter replacement intervals.Advantages of universal joints with slotted bearings include their robust design, which enhances the joint's ability to withstand heavy loads and prolonged use without compromising performance. The slotted bearings and their retention mechanism provide a secure fit that reduces the risk of loosening or failure, contributing to improved reliability and safety in heavy-duty applications.

When it comes to replacement, Universal joints with slotted bearings with slotted bearings should be replaced whenever significant wear or damage is detected during inspections. This could include visible signs of wear on the bearings or the slotted groove, increased play in the joint beyond acceptable limits, or any indication of potential mechanical failure. Manufacturers' maintenance guidelines and service intervals should always be followed to ensure optimal performance and longevity of these critical components.

Regular and proactive maintenance of universal joints with slotted bearings is essential for ensuring the continued reliability and safety of heavy-duty trucks. By adhering to recommended inspection intervals and promptly addressing any issues identified, truck operators can minimize the risk of unexpected downtime and costly repairs, while maximizing the lifespan and performance of these vital components in their fleet.

English

English Español

Español 中文简体

中文简体

Contact Us