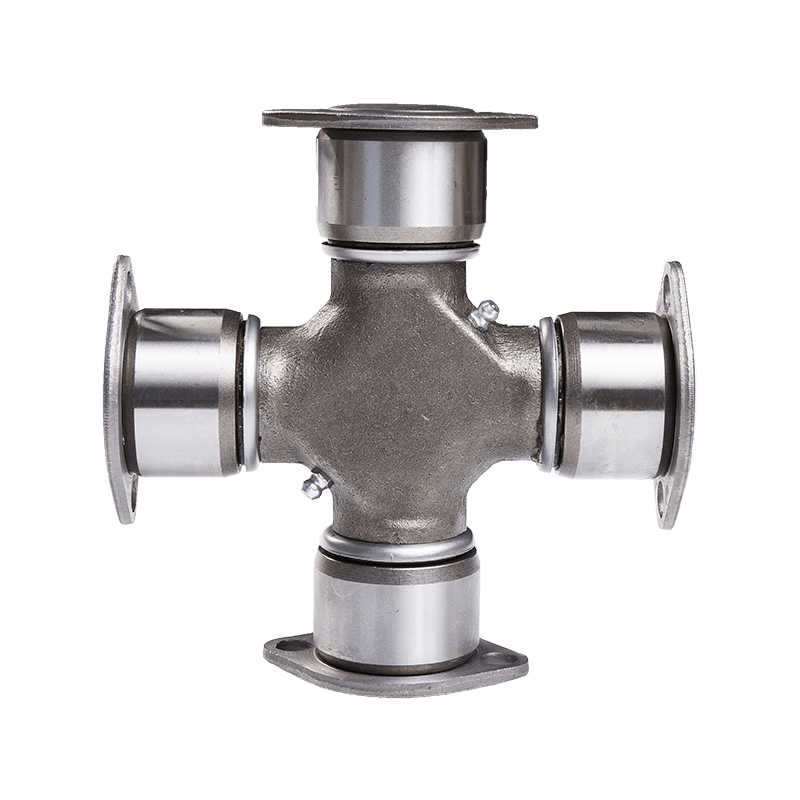

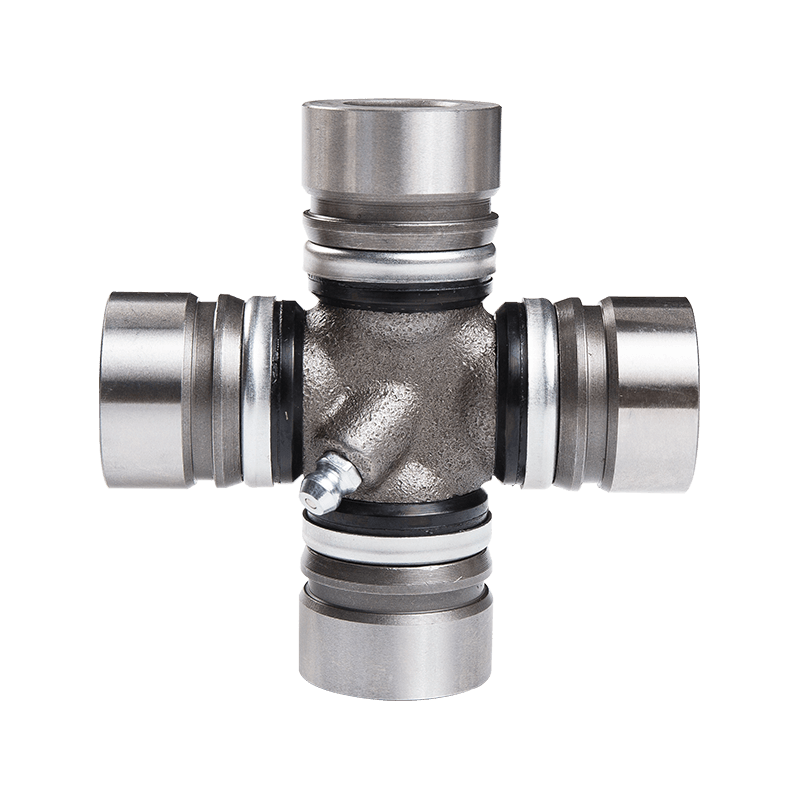

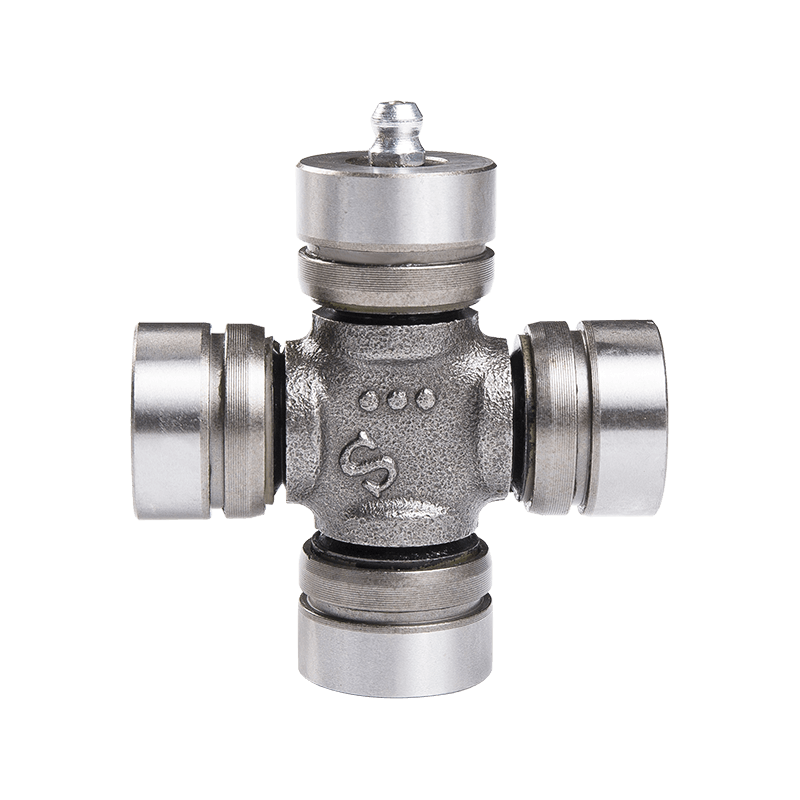

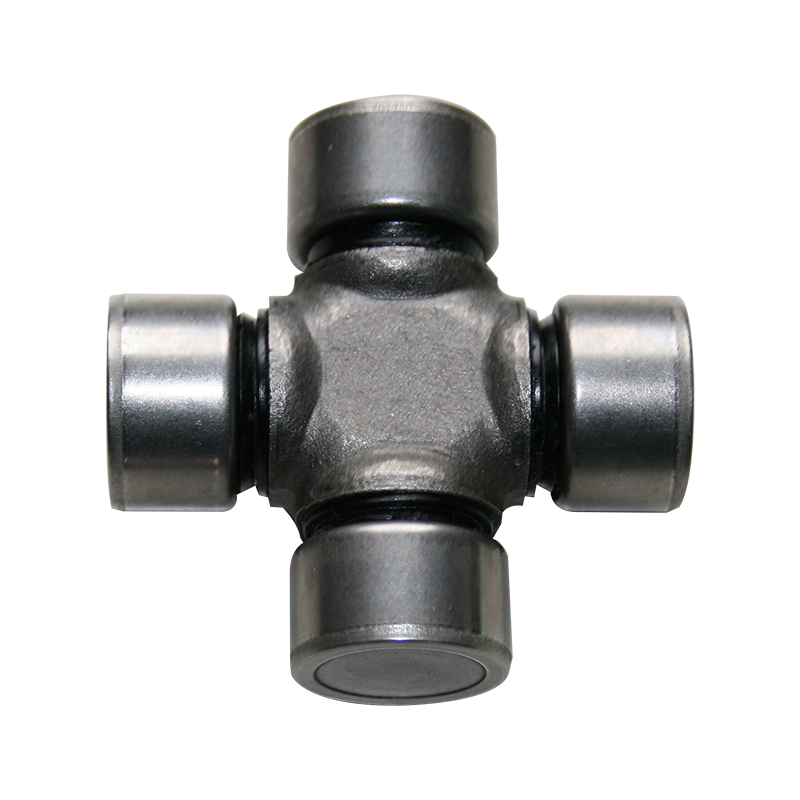

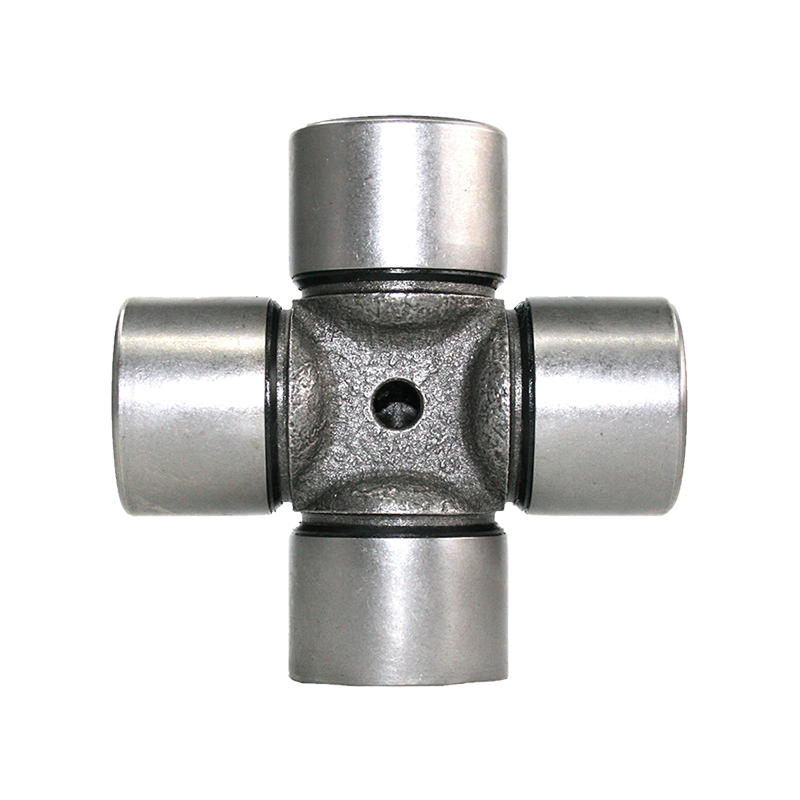

"Universal Joint 5-178X/GU2200 Inner Seal Design, Long Using Life And Easy Assembling" How to design to prevent contaminants from entering the joint?

Material Selection: Choose durable and resilient materials for the inner seal that are specifically designed to resist degradation when exposed to contaminants, such as dust, dirt, water, or other particles. Materials like rubber compounds, silicone, or specialized polymers may be suitable for creating effective seals.

Seal Structure: Design the seal with an appropriate structure to ensure a tight fit between the components it's sealing. Utilize technologies such as lip seals, gaskets, labyrinth seals, or multi-stage sealing systems that prevent contaminants from passing through.

Seal Integrity: Ensure the seal is securely seated within the U-joint to prevent gaps or spaces that could allow contaminants to enter. Proper installation and a snug fit are crucial to maintaining seal integrity.

Smooth Surfaces: Ensure the surfaces where the seal contacts are smooth and free from irregularities to prevent gaps that could compromise the seal's effectiveness.

Seal Compression: Design the seal to apply a certain level of compression when fitted into place, ensuring a tight seal without over-compression that might damage the seal.

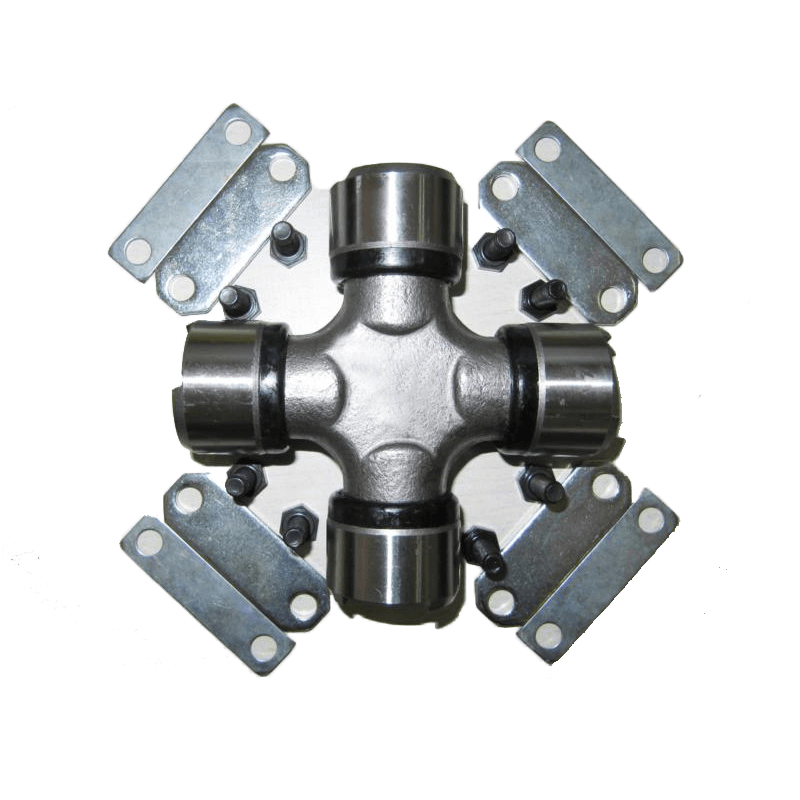

Misalignment Accommodation: Incorporate design features that allow the seal to accommodate potential misalignments between the shafts connected by the U-joint. This can prevent the seal from being compromised due to shaft movement.

Protective Features: Consider integrating additional protective features such as covers, shields, or extra layers of sealing to further shield the joint from potential contaminants.

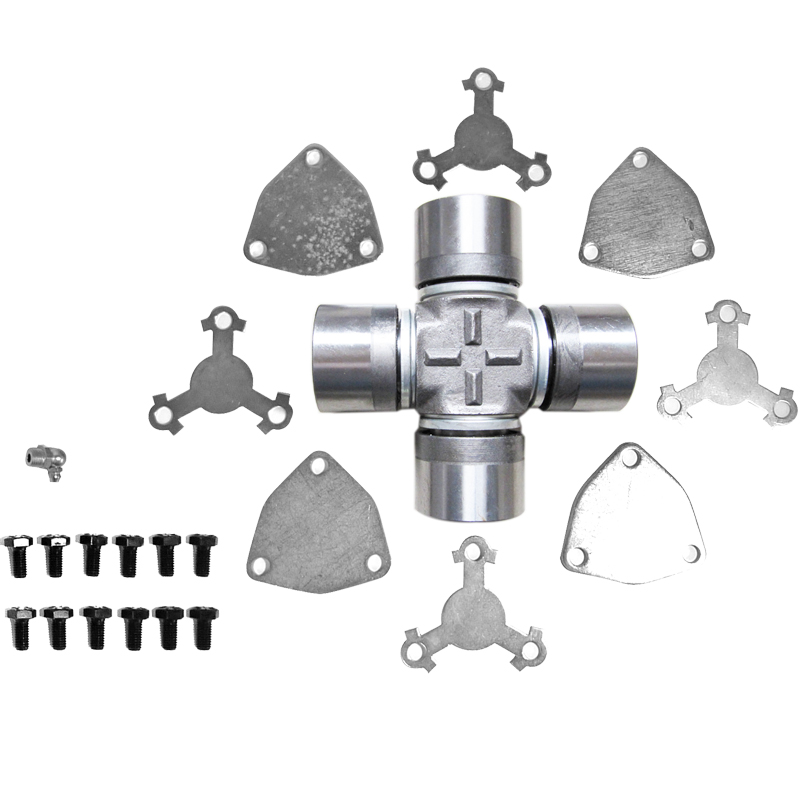

Regular Maintenance Recommendations: Provide guidelines for regular inspection and maintenance of the inner seal. This could involve periodic checks for wear, tear, or damage, as well as a recommended replacement schedule.

Quality Control Measures: Implement quality control measures during the manufacturing process to ensure the inner seal's consistency and effectiveness, verifying that each seal meets specific standards.

What type of sealing process does "Universal Joint 5-178X/GU2200 Inner Seal Design, Long Using Life And Easy Assembling " use?

The product description suggests a focus on achieving a long service life and ease of assembly. The details of the sealing process might not be explicitly mentioned in the product description but could include various sealing methods or technologies designed to meet the intended goals of durability and easy assembly.

Potential types of sealing processes that could be employed in achieving these objectives might include:

Lip Seals: These are common in automotive and industrial applications. They create a seal by the contact between the lips of the seal and the shaft, preventing the entry of contaminants.

Gasket Seals: A gasket is a mechanical seal that fills the space between two or more mating surfaces, often used in environments where compression sealing is required.

Labyrinth Seals: Labyrinth seals consist of a series of grooves or teeth that create a tortuous path, hindering the passage of contaminants into the joint.

Multi-stage Sealing Systems: These could involve a combination of various seal types, arranged in stages to provide added protection against contaminants.

Press-fit Seals: These seals are designed to be press-fit into the joint, ensuring a secure and tight seal without the need for additional adhesive or fasteners.

The emphasis on "long using life and easy assembling" in the product description implies that the inner seal design might incorporate technologies or materials that focus on durability and user-friendly assembly. However, without specific technical details provided by the manufacturer, it's challenging to precisely identify the exact type of sealing process used in the "

Universal Joint 5-178X/GU2200 Inner Seal Design, Long Using Life And Easy Assembling ."

English

English Español

Español 中文简体

中文简体