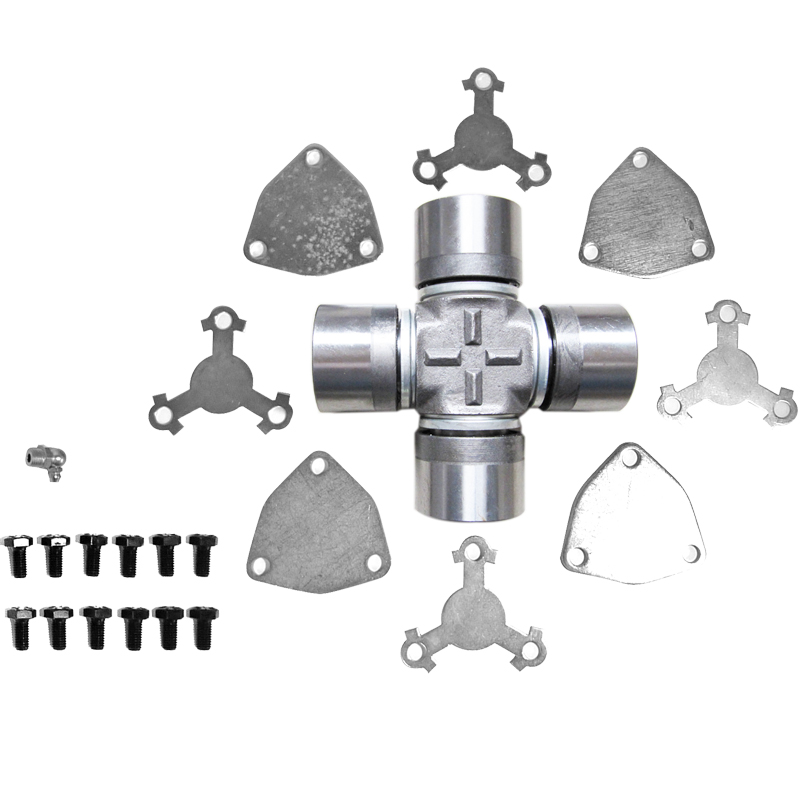

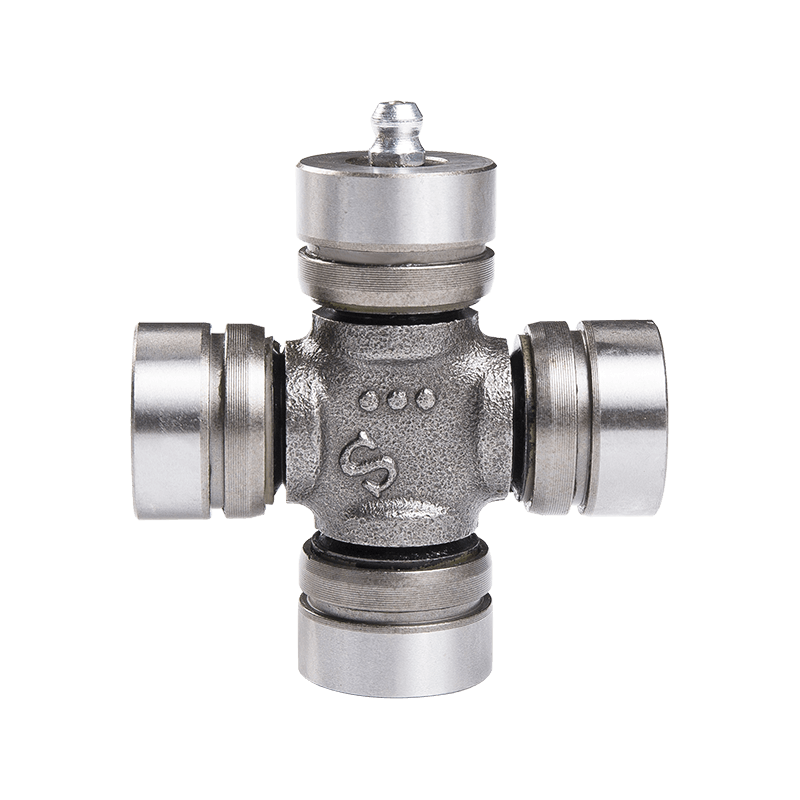

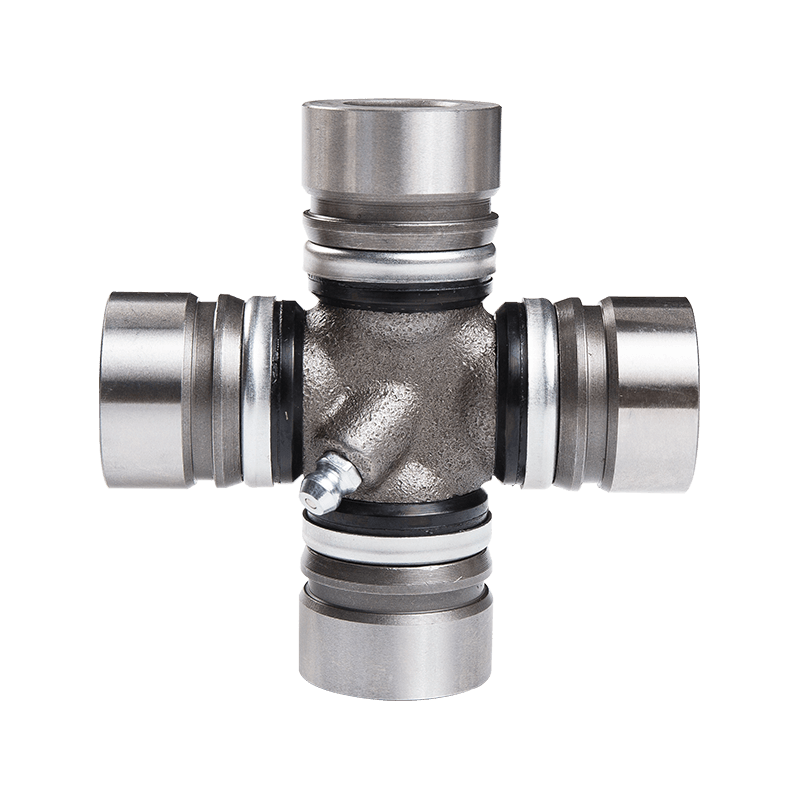

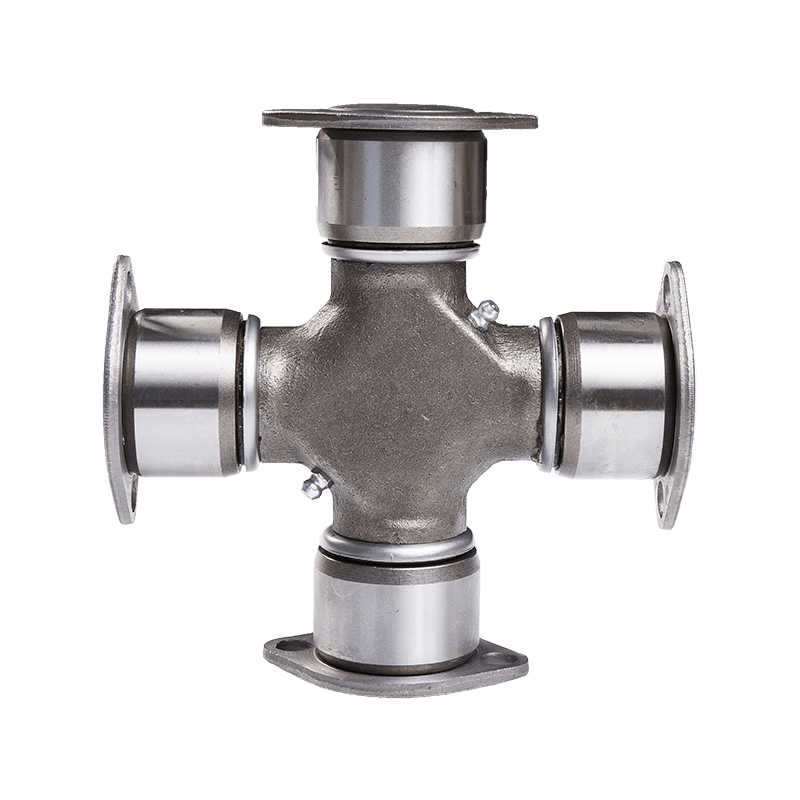

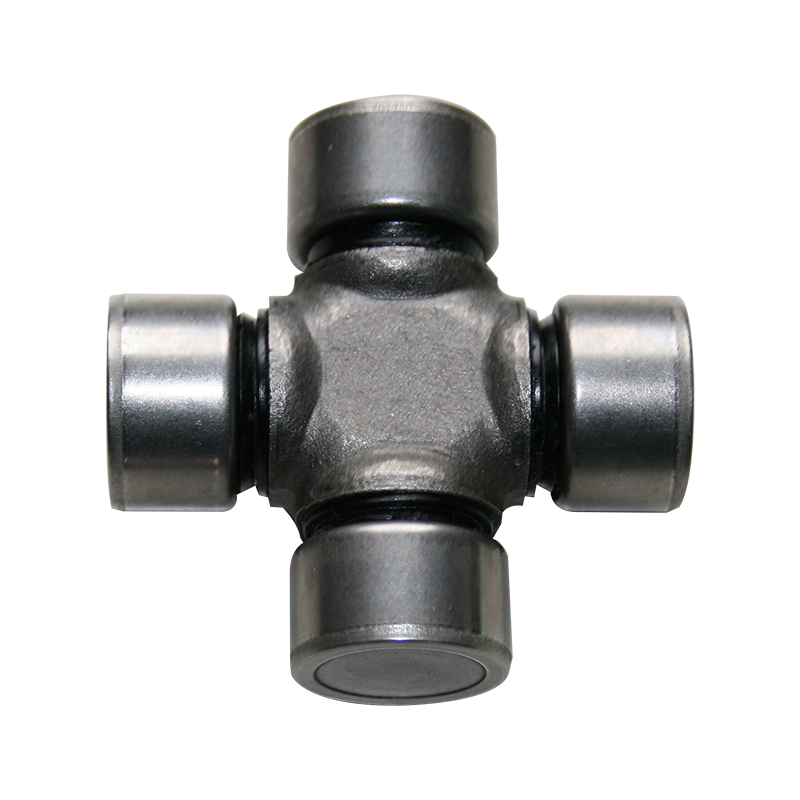

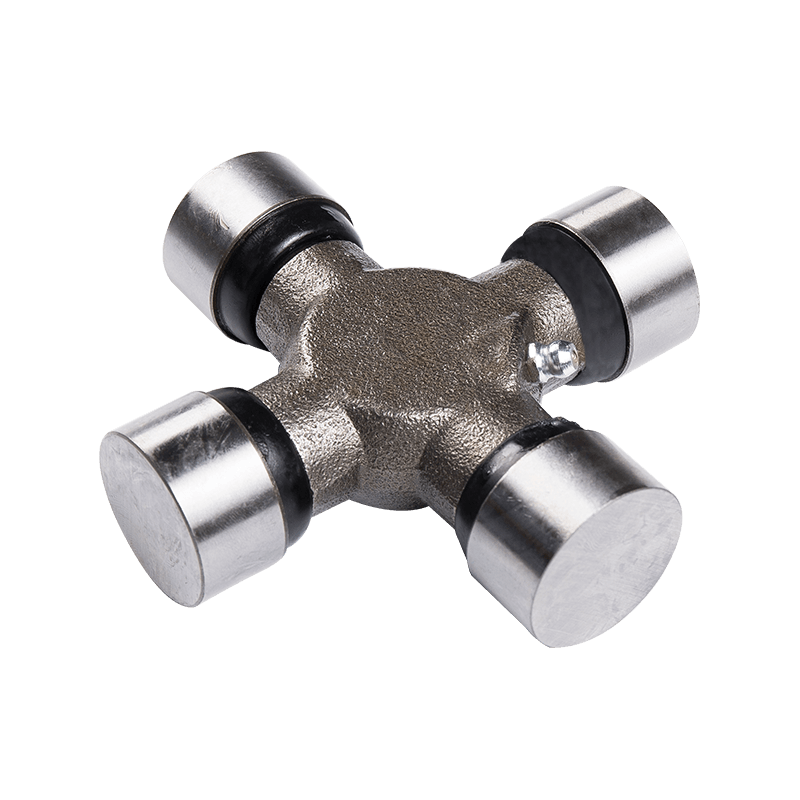

In the realm of mechanical engineering and automotive design, the universal joint with outside snap rings plays a critical role in transferring torque and rotational motion between shafts that are misaligned. These joints are prevalent due to their ability to accommodate changes in angle while maintaining smooth and reliable operation. The snap rings in these joints, which are essential for securing the bearing cups within the yokes, are often made from specific materials chosen for their durability and performance under stress.

The most commonly used materials for snap rings are high-carbon steel, stainless steel, and alloy steel. High-carbon steel is favored for its excellent hardness and strength, which are crucial for withstanding the stresses encountered in mechanical applications. This type of steel is heat-treated to increase its hardness, making it resistant to deformation and wear. However, its susceptibility to corrosion means it is often coated or treated to prevent rust, particularly in environments exposed to moisture or chemicals.

Stainless steel snap rings are another popular choice, especially in applications where corrosion resistance is paramount. Stainless steel contains chromium, which forms a protective layer on the surface, preventing rust and corrosion. This makes stainless steel snap rings ideal for use in harsh environments where exposure to moisture or chemicals is a concern. Despite being more expensive than high-carbon steel, the long-term benefits of stainless steel, such as reduced maintenance and extended service life, often justify the higher initial cost.

Alloy steel snap rings are used in applications that require a balance between strength, toughness, and resistance to wear. Alloy steels are engineered with elements like chromium, molybdenum, or vanadium, which enhance their mechanical properties. These snap rings can handle higher loads and more extreme conditions, making them suitable for heavy-duty applications. They are also often heat-treated to improve their hardness and fatigue resistance, ensuring reliable performance in demanding environments.

The choice of material for snap rings significantly impacts the performance and longevity of the universal joint. For instance, the universal joint with outside snap rings that utilizes high-carbon steel can offer a cost-effective solution while delivering robust performance. Stainless steel variants, though pricier, provide superior resistance to corrosion, making them ideal for automotive or machinery applications exposed to challenging environments. Alloy steel snap rings, while the most specialized, deliver exceptional strength and durability for heavy-duty use.

By understanding the materials used in snap rings, one can better appreciate the engineering behind universal joint with outside snap rings and make informed decisions about their application. The right snap ring material ensures that the universal joint remains secure and operational, which is crucial for maintaining the efficiency and reliability of the machinery or vehicle in which it is used. For instance, a universal joint with an outside snap ring designed with high-carbon steel or stainless steel components will offer a balance of strength and resistance to environmental factors, enhancing the overall performance and lifespan of the joint.

English

English Español

Español 中文简体

中文简体

Contact Us