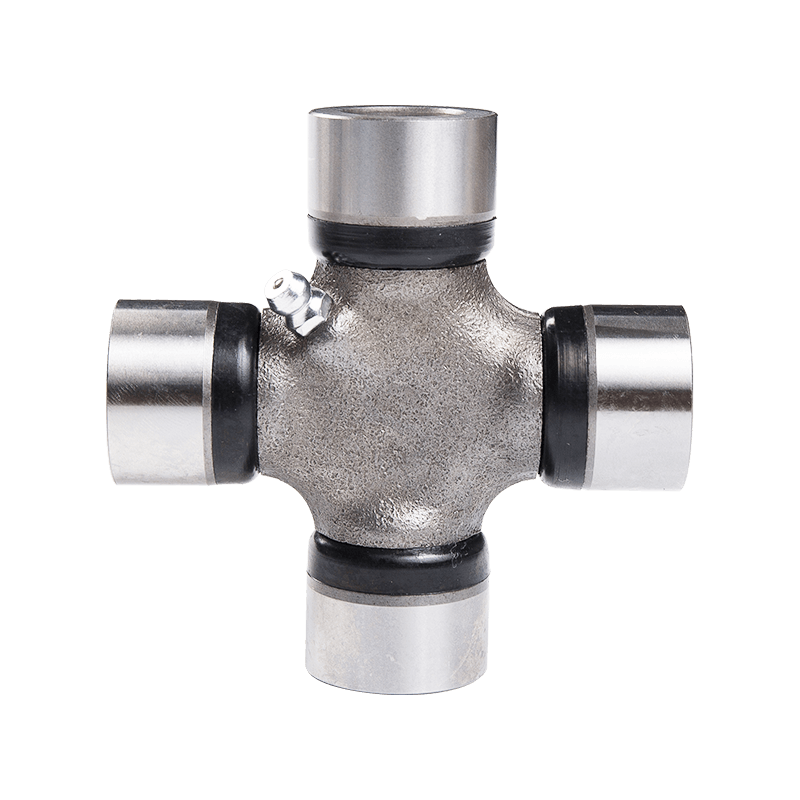

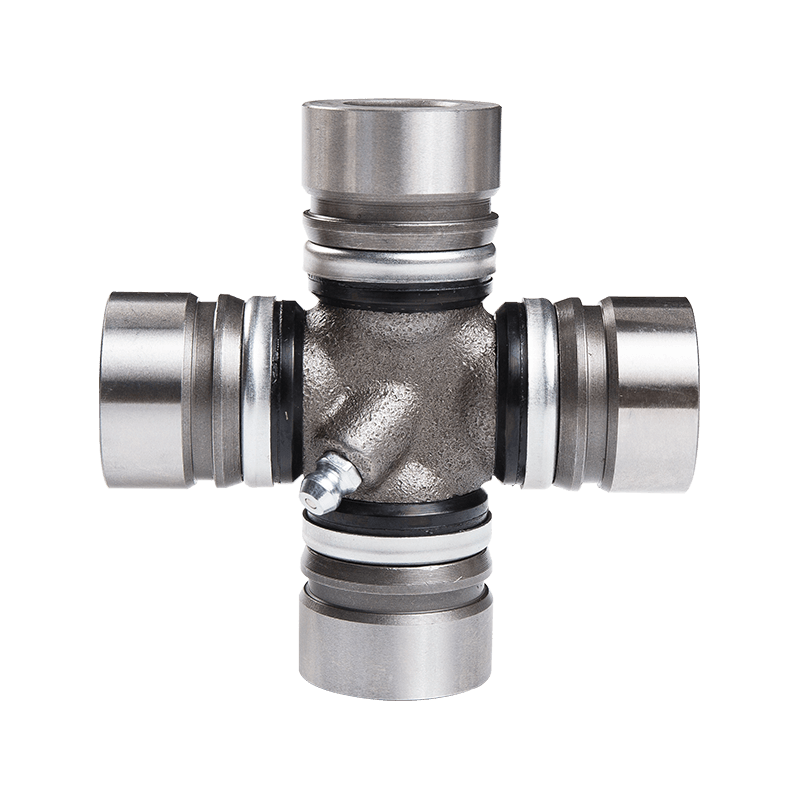

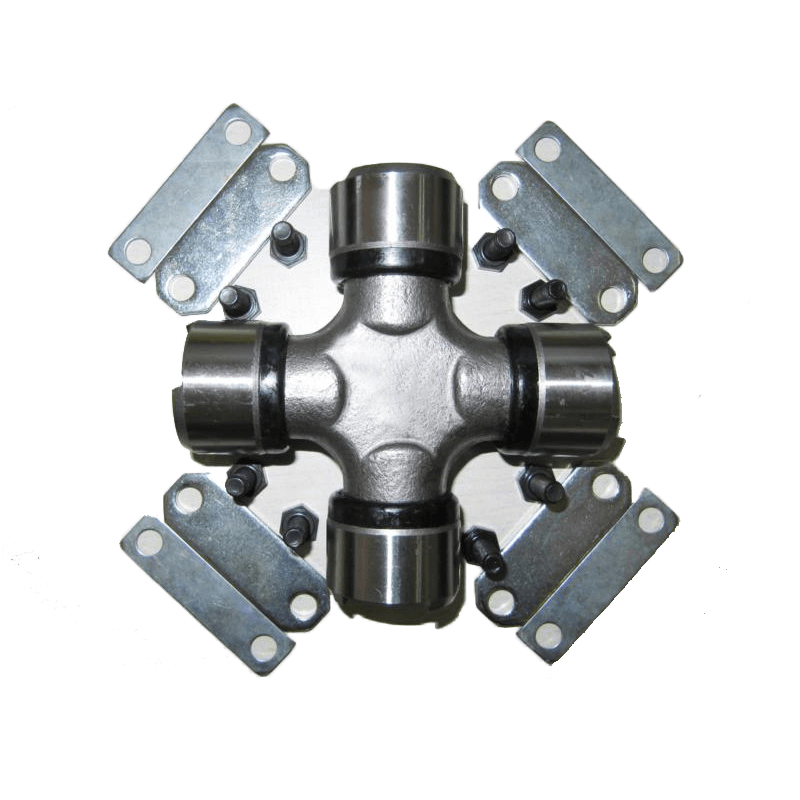

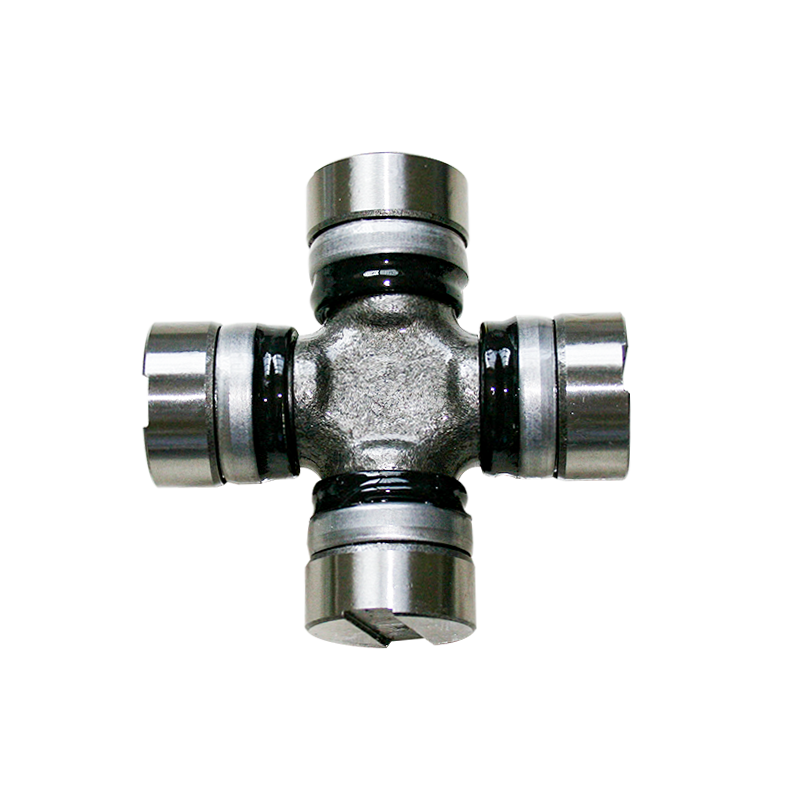

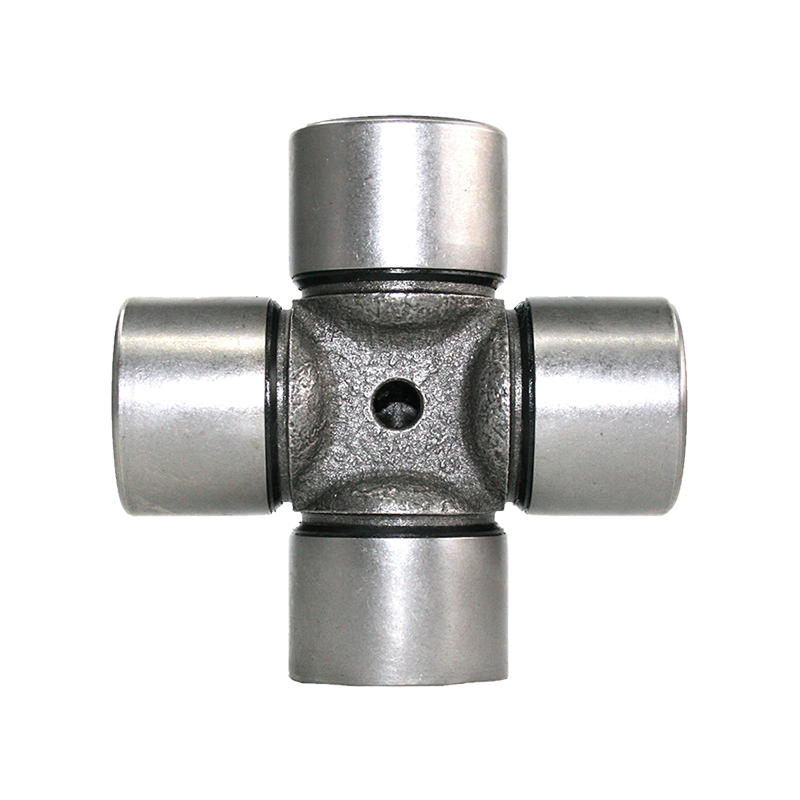

Cardan Universal Joints, named after the Italian mathematician and physicist Girolamo Cardano who invented them in the 16th century, have a rich history marked by significant developments in design and application. These joints, initially conceived to transmit rotational motion between misaligned shafts in industrial machinery, have evolved over centuries to become indispensable components in various fields, particularly automotive engineering.

Early Origins and Industrial Applications

In the early days of mechanical engineering,

Cardan Universal Joints found widespread use in mills, water pumps, and other industrial machinery. Their ability to transfer power efficiently between non-collinear shafts made them essential for transmitting rotational motion in situations where shaft alignment was challenging.

Pioneering Role in Automobiles

As automobiles began to revolutionize transportation, Cardan Universal Joints played a crucial role in transmitting power from the engine to the rear wheels, particularly in early rear-wheel-drive vehicles. This application highlighted the versatility and reliability of these joints in automotive engineering.

Advancements in Automotive Technology

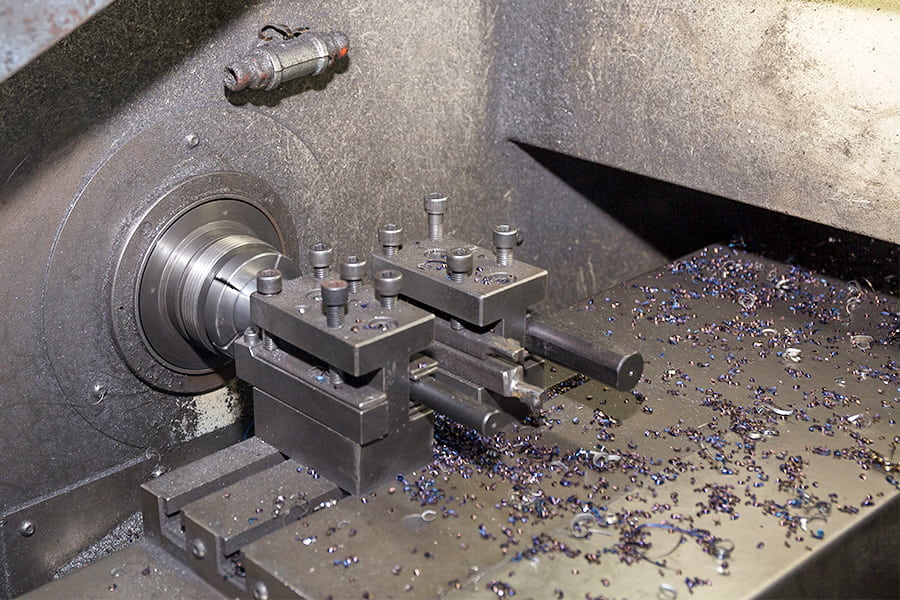

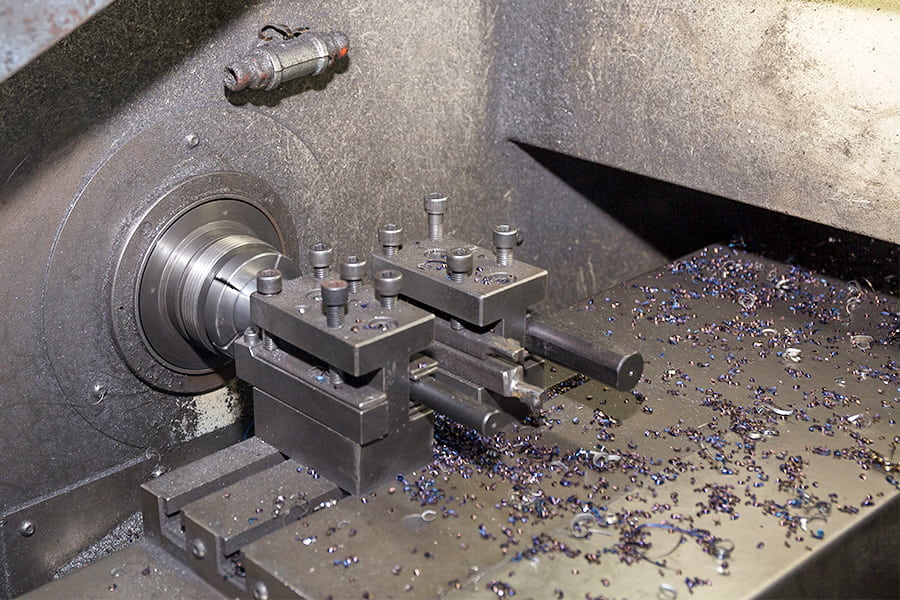

The evolution of automotive technology spurred advancements in Cardan Universal Joint design. Engineers sought to enhance efficiency, durability, and performance, leading to improvements in materials, lubrication systems, and manufacturing techniques. These advancements helped reduce friction, mitigate vibration, and increase the lifespan of Cardan Universal Joints in automotive applications.

Introduction of Constant Velocity Joints (CV Joints)

Despite their effectiveness in transmitting power between misaligned shafts, traditional Cardan Universal Joints introduced velocity fluctuations, leading to vibration and noise in drivetrains. To address these issues, Constant Velocity Joints (CV Joints) were developed. CV Joints provide smoother power transmission, especially in automotive applications, by maintaining constant velocity throughout the rotation.

Diversification into Specialized Fields

Over time, Cardan Universal Joints found application beyond automotive and industrial machinery. They became integral components in aerospace, marine, agricultural equipment, and even in the design of robotics and machinery for space exploration. Their versatility and reliability made them indispensable across various industries.

Integration with Modern Technologies

Advancements in materials science, computer-aided design (CAD), and manufacturing technologies have further enhanced Cardan Universal Joint performance and versatility. These advancements have led to the development of more efficient and durable joints capable of operating under extreme conditions. Ongoing research continues to explore new materials, designs, and applications for Cardan Universal Joints, ensuring their relevance in the ever-evolving landscape of engineering.

In conclusion, the historical evolution of

Cardan Universal Joints showcases the relentless pursuit of innovation to meet the evolving needs of industries. From their humble beginnings in industrial machinery to their ubiquitous presence in modern-day automotive and aerospace engineering, these joints remain indispensable components, driving progress and efficiency across various sectors.

English

English Español

Español 中文简体

中文简体

Contact Us