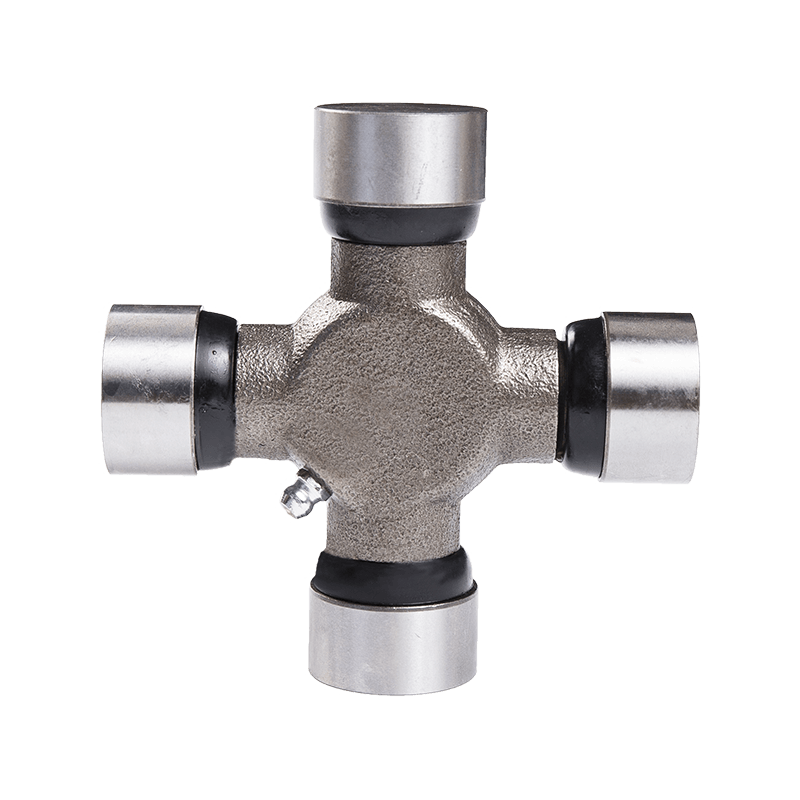

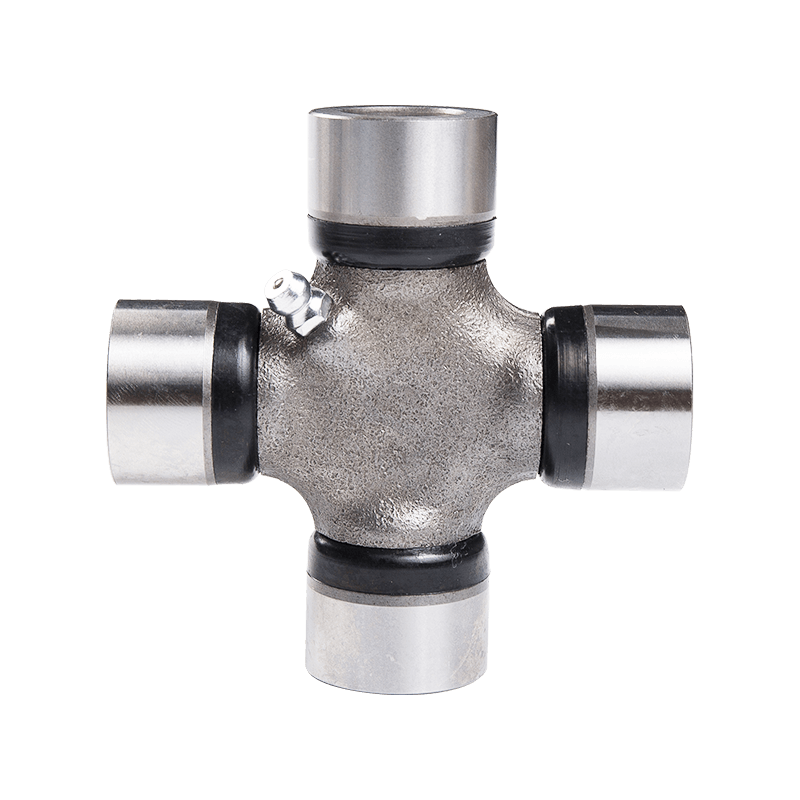

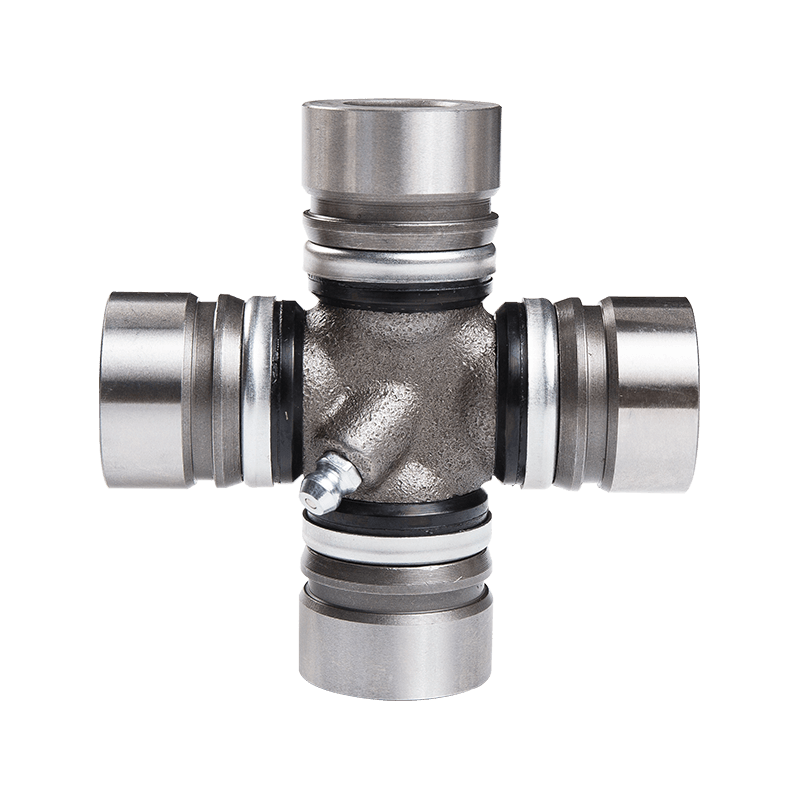

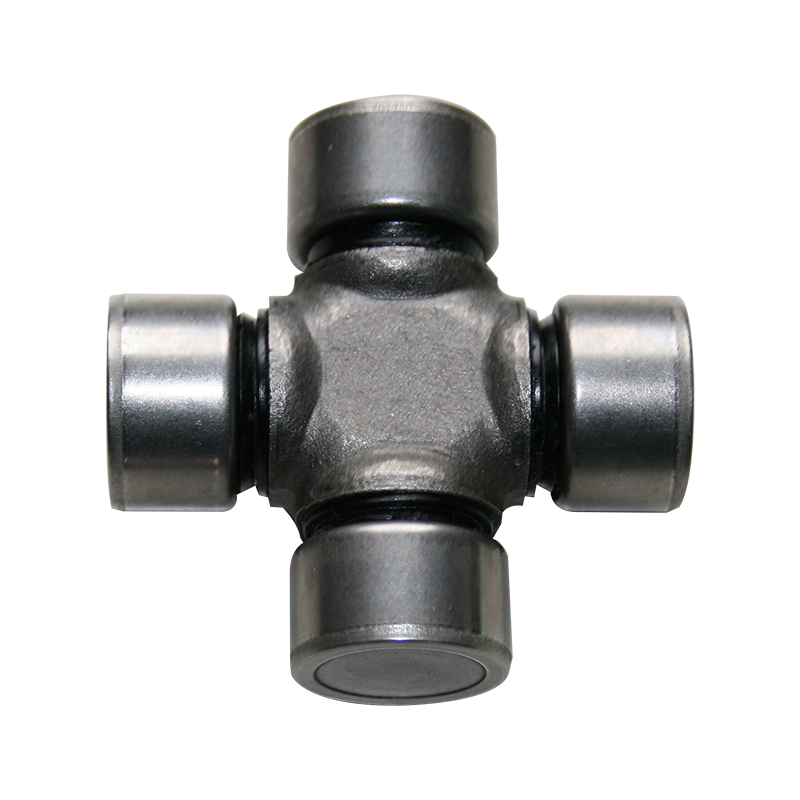

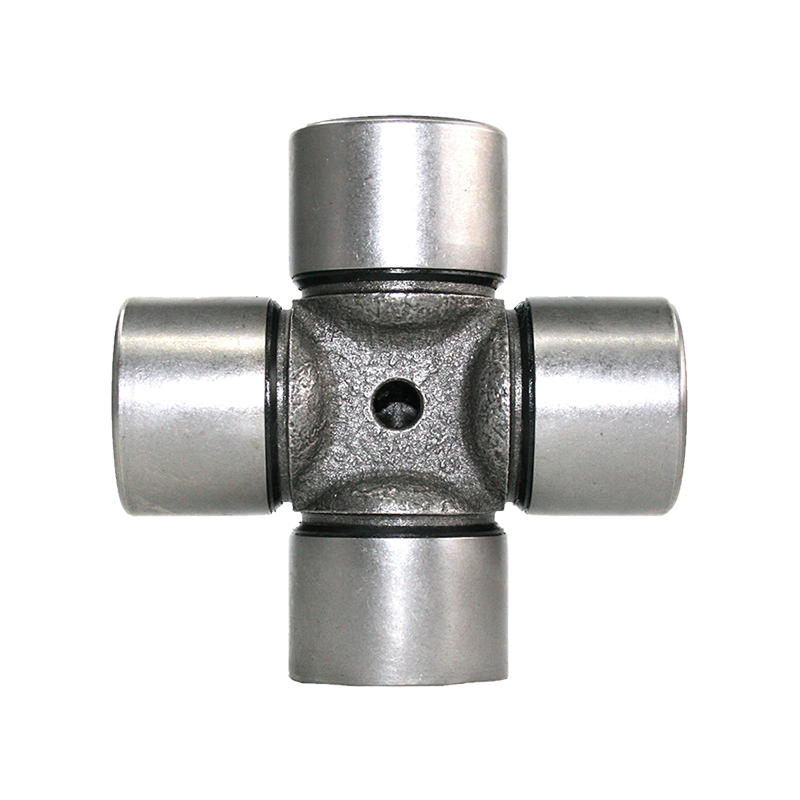

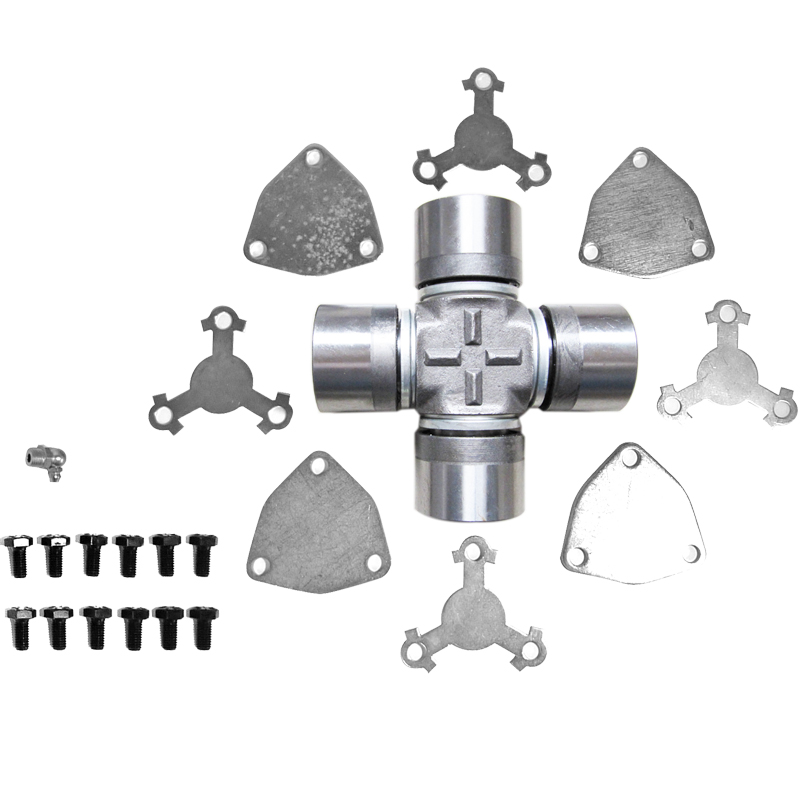

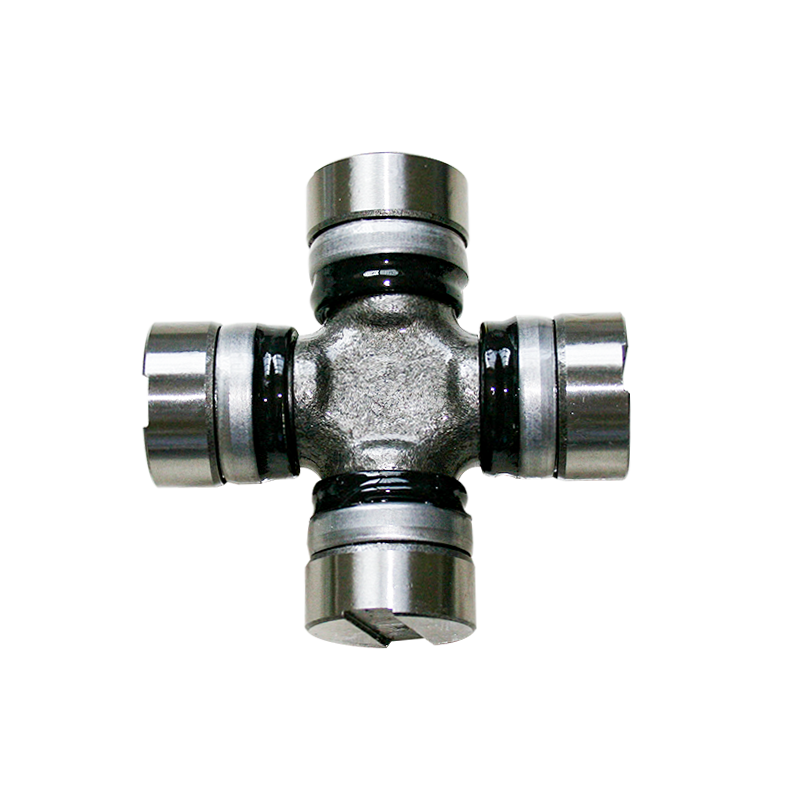

The quest for reliability, efficiency, and reduced maintenance requirements is perpetual. One innovation that has significantly contributed to meeting these demands is the advent of maintenance-free universal joints. These versatile components, which eliminate the need for regular lubrication, have found profound applications across various industries, revolutionizing traditional power transmission systems. Let's delve into the industries and applications that benefit most from the utilization of maintenance-free universal joints.

Automotive and Transportation:

The automotive sector, encompassing vehicles ranging from personal cars to heavy-duty trucks, benefits immensely from maintenance-free universal joints. These joints play a critical role in driveshafts and steering systems, ensuring smooth power transmission without the hassle of frequent lubrication. In a fast-paced industry where downtime is costly, maintenance-free universal joints offer reliability and longevity, making them indispensable components in modern vehicles.

Agriculture and Farming:

In the agricultural domain, where machinery operates in harsh environments and remote locations, maintenance-free universal joints shine. Tractors, harvesters, and irrigation systems rely on these joints for dependable power transmission, even in dusty or muddy conditions. By eliminating the need for regular greasing, maintenance-free universal joints minimize downtime and contribute to uninterrupted farming operations, ultimately boosting productivity.

Construction and Heavy Machinery:

Construction equipment, characterized by heavy loads and rugged environments, demands robust power transmission solutions. Maintenance-free universal joints excel in this arena, providing reliable performance in excavators, cranes, and earthmoving machinery. Their ability to withstand extreme conditions while requiring minimal maintenance ensures continuous operation and enhances efficiency in construction projects.

Industrial Machinery:

Across various industrial applications, including manufacturing, processing, and material handling, maintenance-free universal joints offer a maintenance-free solution for critical machinery components. From conveyor systems to robotics, these joints facilitate smooth power transmission, reducing the risk of equipment downtime due to lubrication issues. Industries benefit from improved productivity and reduced maintenance costs associated with maintenance-free universal joints.

Marine and Offshore:

Marine environments pose unique challenges, including corrosion and harsh weather conditions, making reliability a top priority for marine equipment. Maintenance-free universal joints are preferred for marine propulsion systems, steering linkages, and other maritime applications due to their resistance to corrosion and minimal maintenance requirements. These joints ensure continuous operation, contributing to the efficiency and safety of marine vessels and offshore structures.

Mining and Quarrying:

In the mining and quarrying industry, where equipment operates in abrasive and challenging conditions, maintenance-free universal joints provide a reliable solution for power transmission. Crushers, drills, and conveyors benefit from the durability and longevity of these joints, minimizing downtime and maximizing productivity in mining operations.

Renewable Energy:

The renewable energy sector, particularly wind turbines and solar tracking systems, relies on maintenance-free universal joints for efficient power transmission. These joints offer a maintenance-free solution for critical components, ensuring continuous operation and minimizing servicing requirements in remote locations. By enhancing reliability and efficiency, maintenance-free universal joints contribute to the growth of renewable energy generation.

English

English Español

Español 中文简体

中文简体

Contact Us