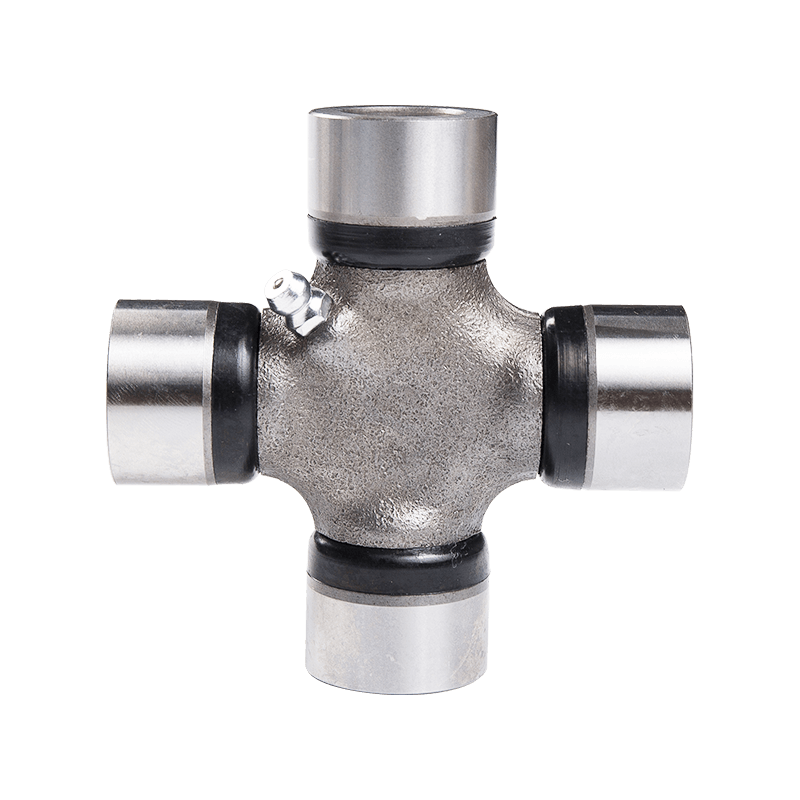

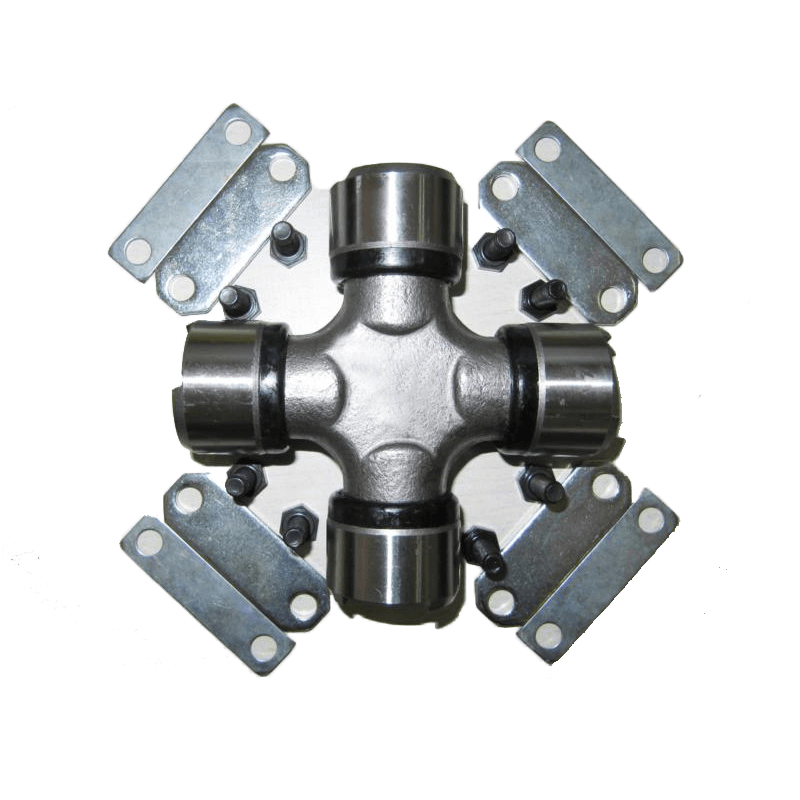

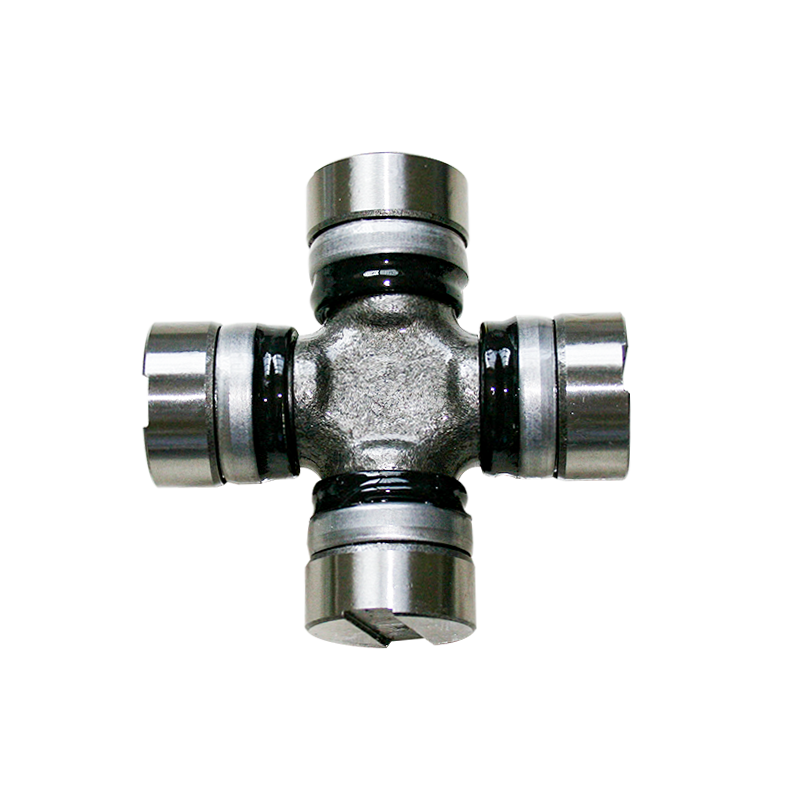

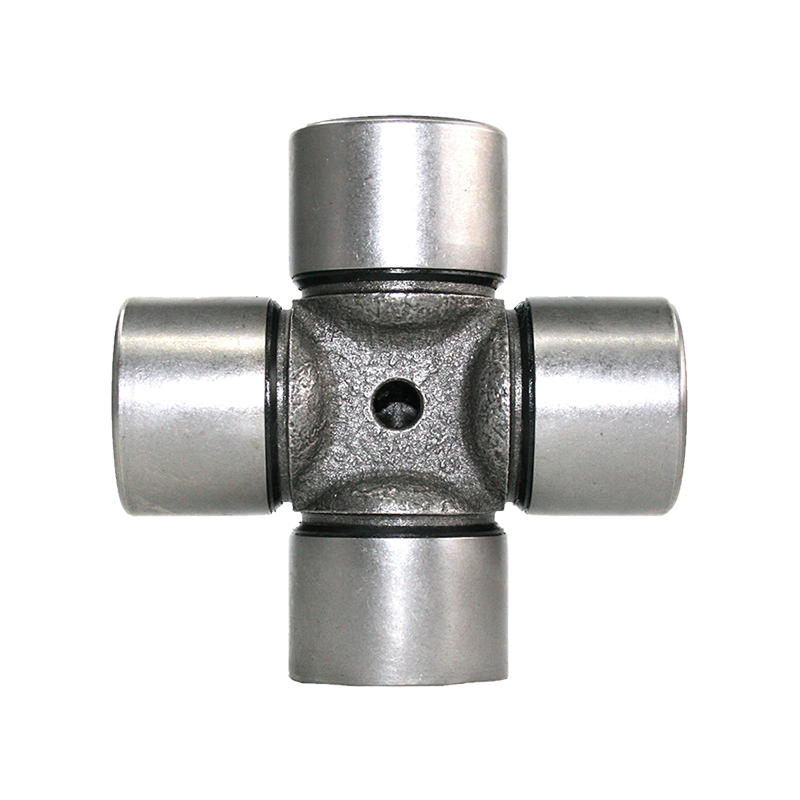

In the intricate world of mechanical engineering, where precision meets practicality, the universal joint stands as a testament to ingenuity. Yet, within its seemingly simple design lies a critical component that often goes unnoticed—the wing bearing. These unassuming elements play a pivotal role in enhancing the functionality of universal joints, contributing to their efficiency, flexibility, and durability in a myriad of applications.

At the heart of every universal joint with wing bearings lies the fundamental principle of torque transmission. Imagine a scenario where rotational force must seamlessly traverse from one shaft to another, overcoming obstacles such as misalignment and shock loads. This is where wing bearings shine. By providing a stable interface between the connecting fitting yokes and the bearing blocks, they ensure that torque flows smoothly and consistently, powering machinery with precision and reliability.

But wing bearings offer far more than mere torque transmission. In a world where mechanical systems face constant challenges, adaptability is key. Here, wing bearings excel by accommodating movement and misalignment with grace. Whether it's angular deviation, parallel misalignment, or axial displacement, these bearings flex and adjust, maintaining optimal performance even in less-than-ideal conditions. Picture a driveshaft in a heavy-duty truck navigating rough terrain—thanks to wing bearings, it withstands the twists and turns of the road without skipping a beat.

Shock loads, those sudden bursts of force that threaten to disrupt operations, pose yet another challenge. Yet, with wing bearings in place, the impact is absorbed and dispersed, sparing the universal joint from undue stress. This resilience is especially crucial in industries where machinery operates under constant duress, from manufacturing plants to mining operations. In these environments, the reliability of wing bearings can mean the difference between uninterrupted production and costly downtime.

Maintenance is another aspect where wing bearings prove their worth. Designed for accessibility and ease of service, they allow technicians to perform repairs without dismantling the entire universal joint with wing bearings assembly. This not only minimizes downtime but also reduces maintenance costs, making them a practical choice for industries that demand efficiency and reliability.

The hallmark of any well-engineered component, is where wing bearings truly shine. Constructed with materials resistant to wear, corrosion, and fatigue, they withstand the test of time even in the harshest of environments. Whether it's the relentless heat of an industrial furnace or the corrosive atmosphere of a marine vessel, wing bearings endure, ensuring uninterrupted operation and peace of mind for engineers and operators alike.

English

English Español

Español 中文简体

中文简体

Contact Us