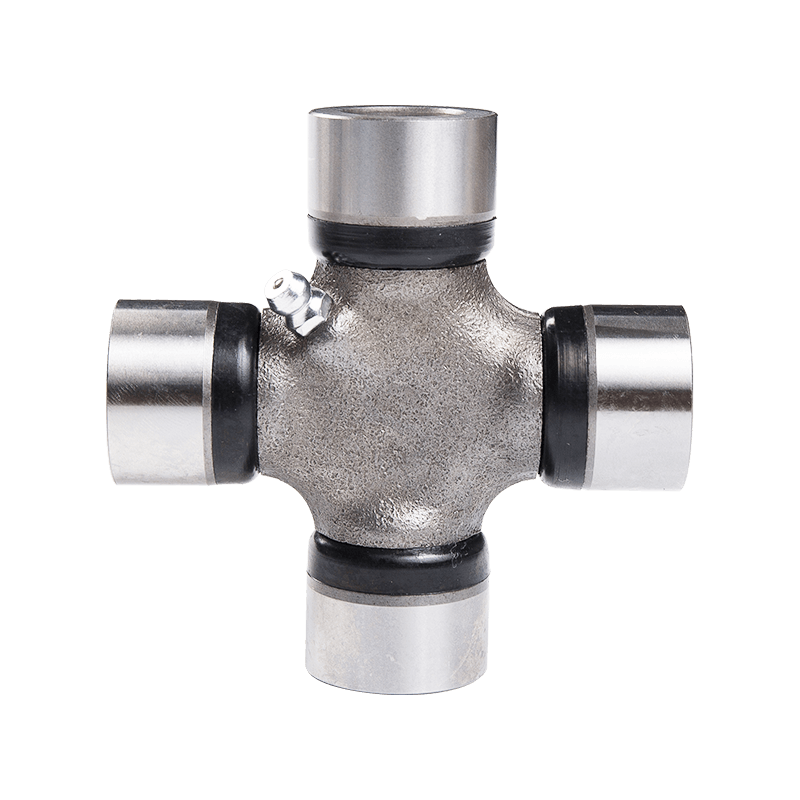

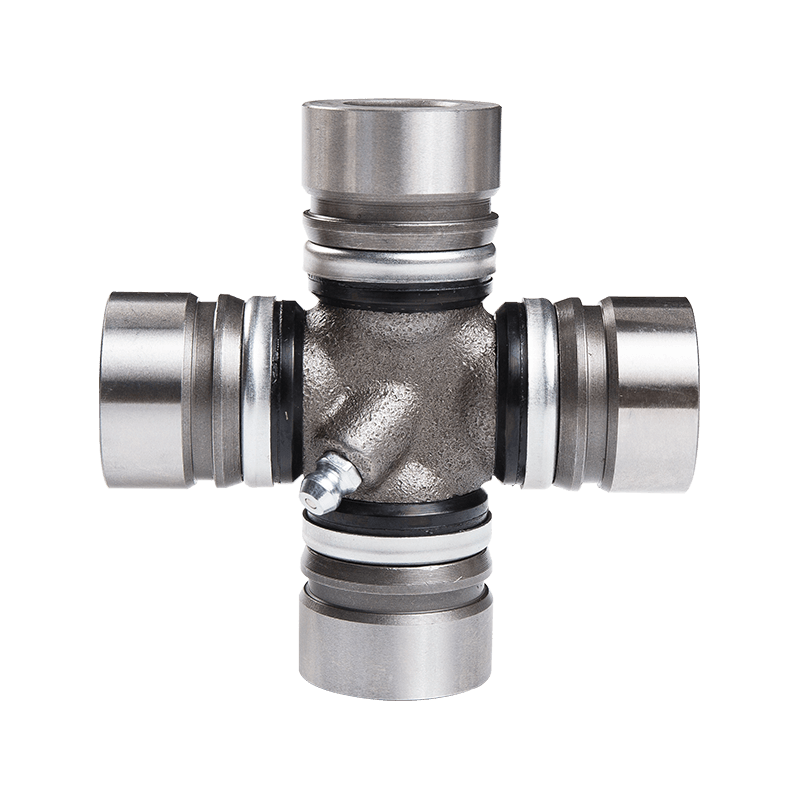

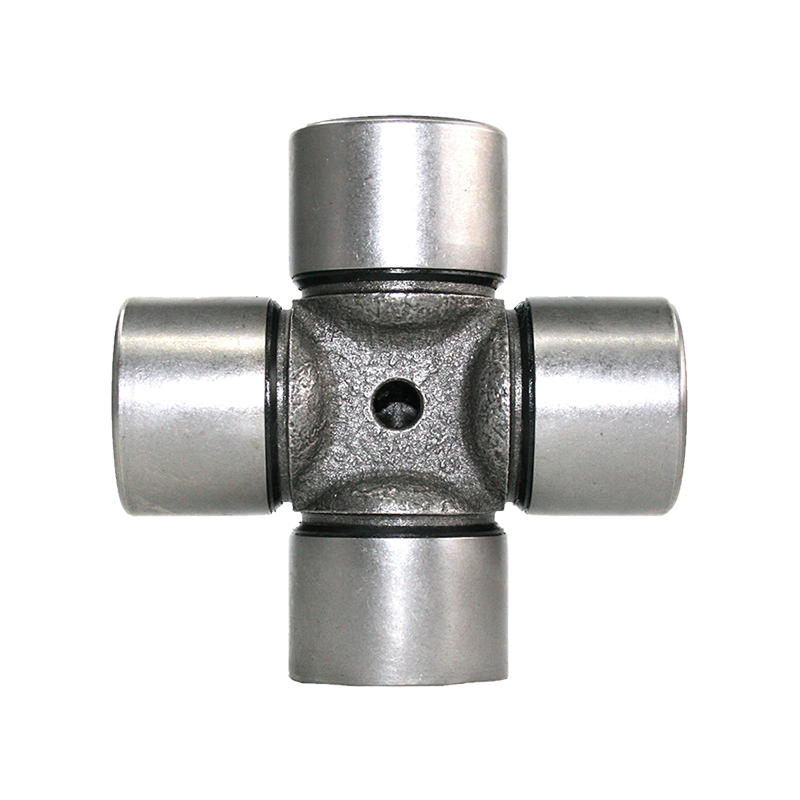

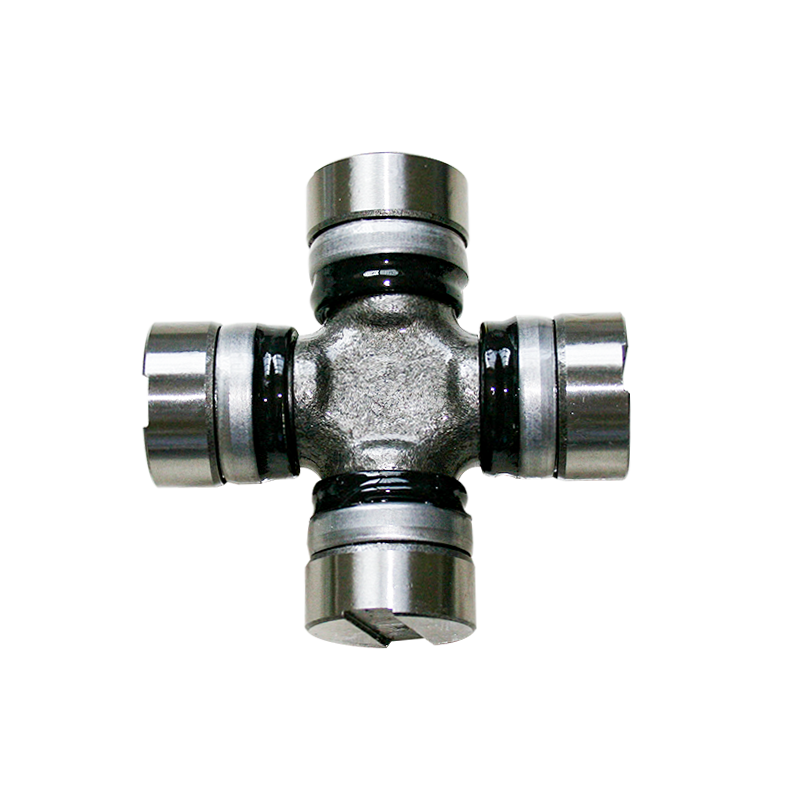

Universal joints (U-joints) are pivotal components in mechanical systems, enabling the transmission of rotational motion between shafts that are not aligned perfectly. Within this realm of U-joints, those equipped with wing bearings stand out for their exceptional durability and reliability. Let’s delve into how wing bearings contribute to enhancing these critical attributes.

Load Distribution and Stress Management

One of the primary roles of wing bearings in Universal Joint With Wing Bearings is their ability to distribute loads effectively. In mechanical systems, varying angles and misalignments can introduce uneven stresses on components. Wing bearings help mitigate this issue by spreading the load across their bearing surfaces. By doing so, they prevent localized stress concentrations that could lead to premature wear or failure of the joint. This load distribution capability is particularly crucial in applications where the joint experiences continuous or fluctuating loads.

Shock Absorption and Impact Resistance

In dynamic environments, such as automotive drivetrains or industrial machinery, U-joints often encounter shock loads and sudden changes in torque. Wing bearings excel in absorbing these impacts due to their design and placement within the joint. They act as buffers between moving parts, dampening the effects of sudden forces and vibrations. This shock absorption capability not only protects the joint from damage but also ensures smooth operation over a prolonged period.

Alignment Stability and Efficiency

Maintaining proper alignment is essential for the efficient operation of U-joints. Wing bearings play a pivotal role in preserving alignment between connected shafts or components. They help stabilize rotational movement, ensuring that the joint operates smoothly even under varying operating conditions. This stability not only enhances efficiency by reducing energy losses due to misalignment but also prolongs the life of associated drivetrain components.

Friction Reduction and Wear Prevention

Friction is a natural byproduct of mechanical motion, leading to wear and energy loss if not properly managed. Wing bearings are designed with smooth bearing surfaces and optimized lubrication channels. These features minimize friction between moving parts within the joint, thereby reducing wear on critical components such as bearing surfaces and shafts. Lower friction levels also contribute to improved efficiency and reduced operating temperatures, further enhancing the overall reliability of the U-joint.

Corrosion Resistance and Longevity

In many industrial and automotive applications, Universal Joint With Wing Bearings are exposed to harsh environmental conditions that can accelerate wear and corrosion. Wing bearings are often crafted from materials such as stainless steel or specialized alloys that offer superior corrosion resistance. This resistance ensures that the bearings maintain their integrity and functionality over extended periods, even in challenging environments. As a result, U-joints equipped with wing bearings exhibit prolonged service life and reliability, making them suitable for critical applications where downtime is costly.

Maintenance and Operational Efficiency

Lastly, the robust design and performance characteristics of wing bearings contribute to reduced maintenance requirements and enhanced operational efficiency. Their ability to withstand demanding conditions without frequent inspection or lubrication intervals translates into lower overall maintenance costs and increased uptime for machinery and vehicles.

English

English Español

Español 中文简体

中文简体

Contact Us