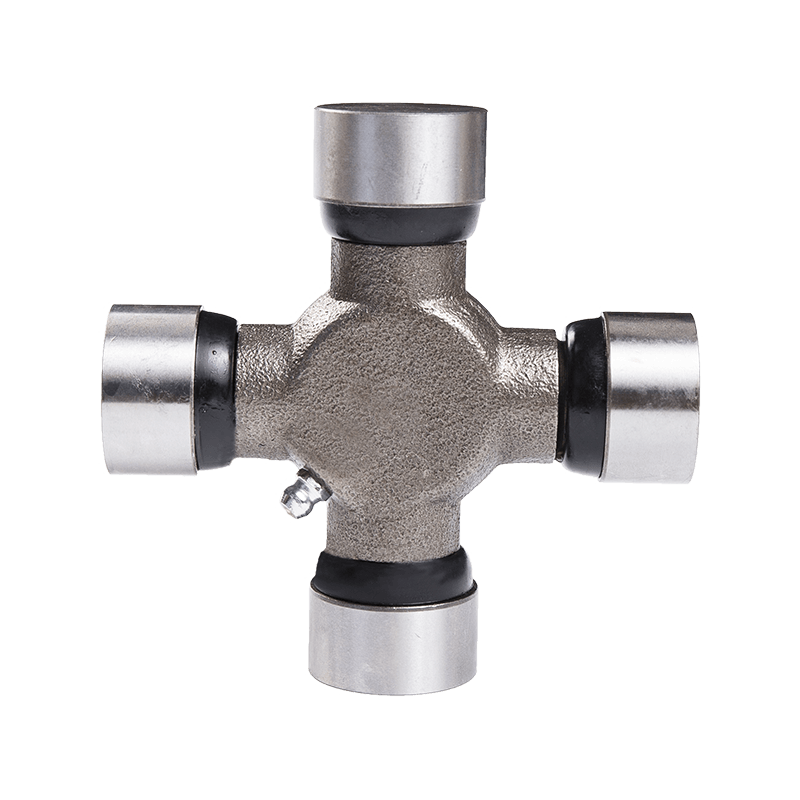

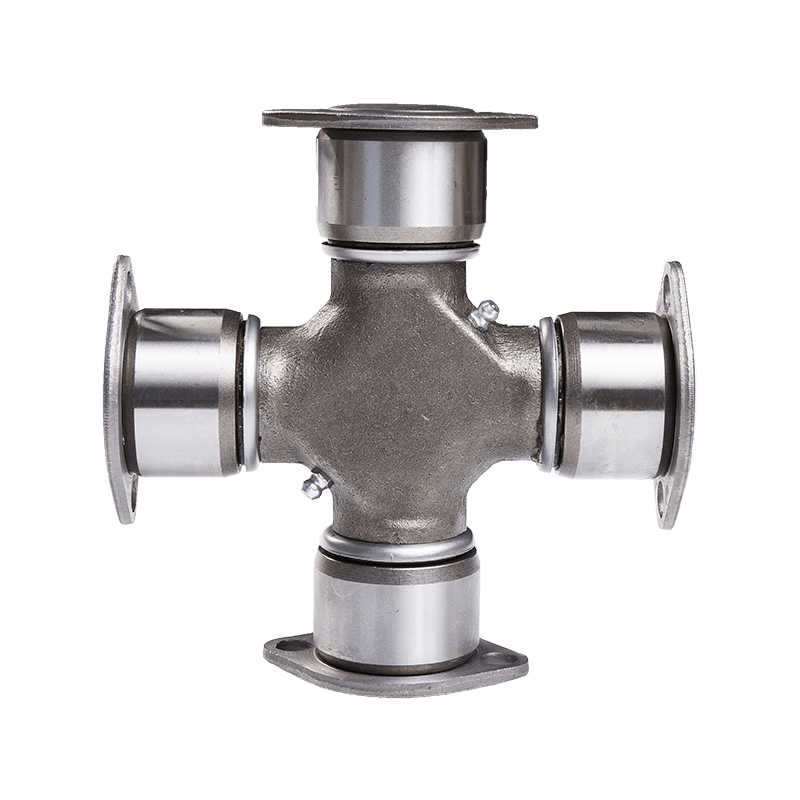

Several factors can contribute to wear and tear on

PTO shaft u-joints. Understanding these causes and implementing preventive measures is crucial for maintaining the efficiency and longevity of the u-joints. Here are common causes and preventive measures:

Lack of Lubrication:

Cause: Insufficient or improper lubrication can lead to increased friction and wear.

Prevention: Regularly lubricate the u-joint according to the manufacturer's recommendations. Use the appropriate lubricant and ensure proper coverage of all moving parts.

Contamination:

Cause: Dust, dirt, water, and other contaminants can infiltrate the u-joint, accelerating wear.

Prevention: Keep the PTO shaft and u-joint components clean. Use protective covers when the equipment is not in use, especially in dusty or wet environments.

Misalignment:

Cause: Operating the PTO shaft at extreme angles or misaligned positions can lead to uneven stress and premature wear.

Prevention: Align the driving and driven components properly during installation. Avoid excessive angular misalignment, and use flexible couplings or constant velocity joints when necessary.

Overloading:

Cause: Subjecting the u-joint to loads beyond its rated capacity can lead to excessive stress and wear.

Prevention: Ensure that the equipment is used within its specified load limits. Select u-joints with appropriate torque and load ratings for the application.

Imbalance:

Cause: Imbalances in the driven components can cause uneven forces on the u-joint, leading to wear.

Prevention: Balance rotating components, such as pulleys or blades, to minimize vibrations. Regularly inspect and replace worn components to maintain balance.

Corrosion:

Cause: Exposure to corrosive environments can lead to rust and deterioration of u-joint components.

Prevention: Apply corrosion-resistant coatings or paints to exposed surfaces. Store equipment in a dry environment when not in use.

Shock Loads:

Cause: Sudden starts, stops, or impacts can result in shock loads that contribute to u-joint wear.

Prevention: Operate the machinery smoothly and avoid abrupt changes in speed or direction. Consider using shock-absorbing devices or couplings.

Inadequate Maintenance:

Cause: Neglecting regular inspections and maintenance can allow minor issues to escalate into major problems.

Prevention: Establish a routine maintenance schedule. Inspect

PTO shaft u-joints for signs of wear, play, or damage, and address issues promptly. Replace worn components as needed.

Incorrect Installation:

Cause: Improper installation, such as incorrect phasing or tight fasteners, can lead to premature u-joint failure.

Prevention: Follow the manufacturer's guidelines for installation. Ensure proper phasing, torque fasteners to specifications, and use appropriate hardware.

English

English Español

Español 中文简体

中文简体

Contact Us