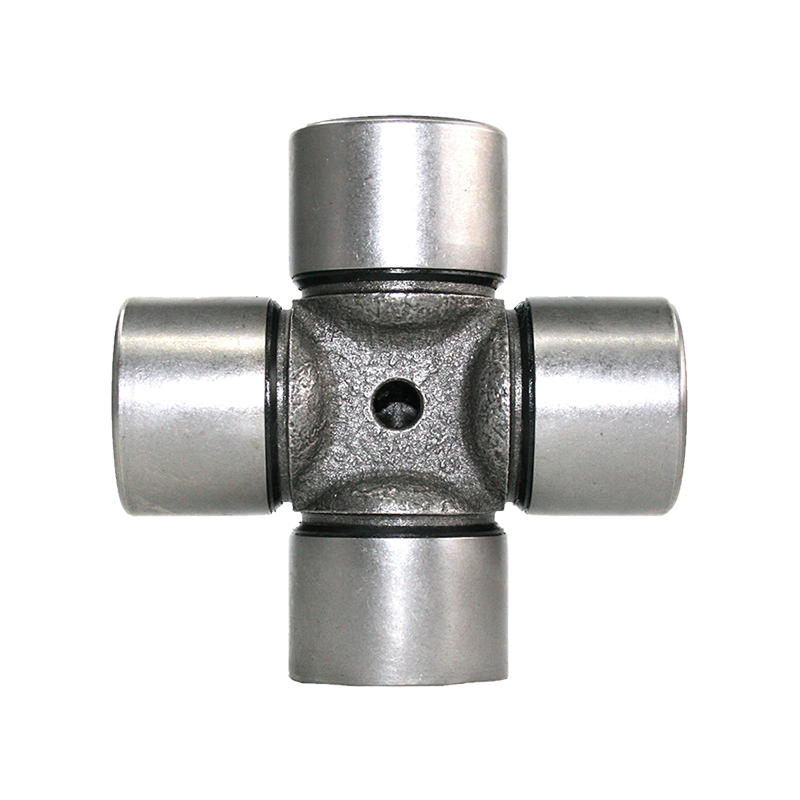

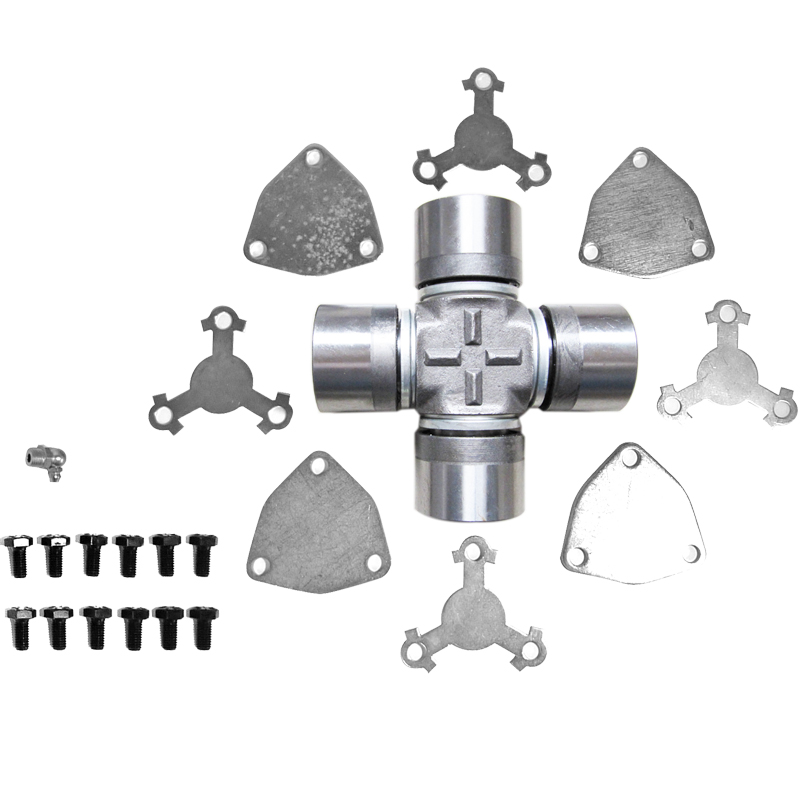

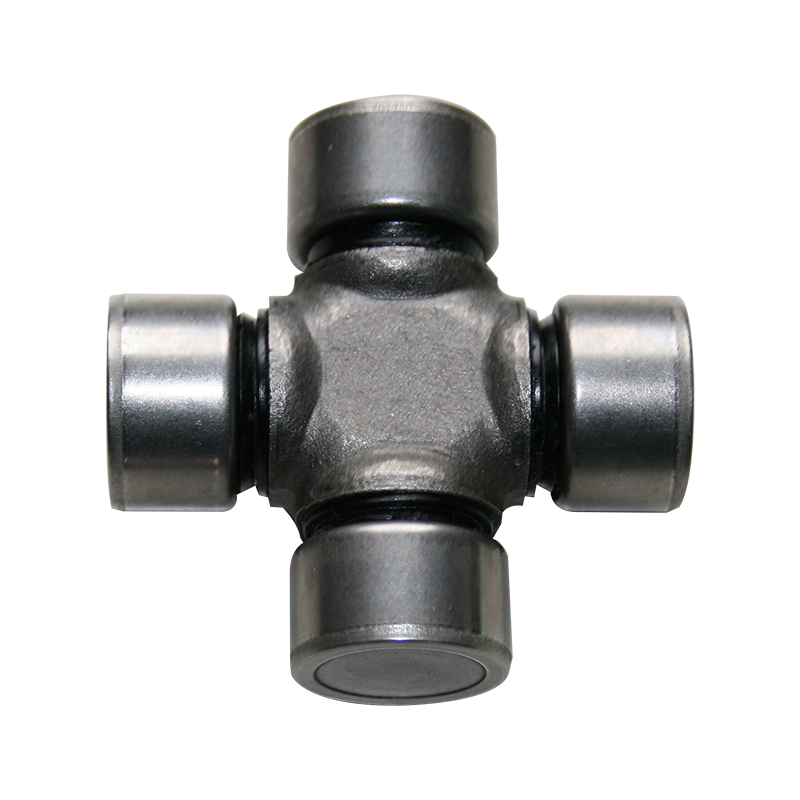

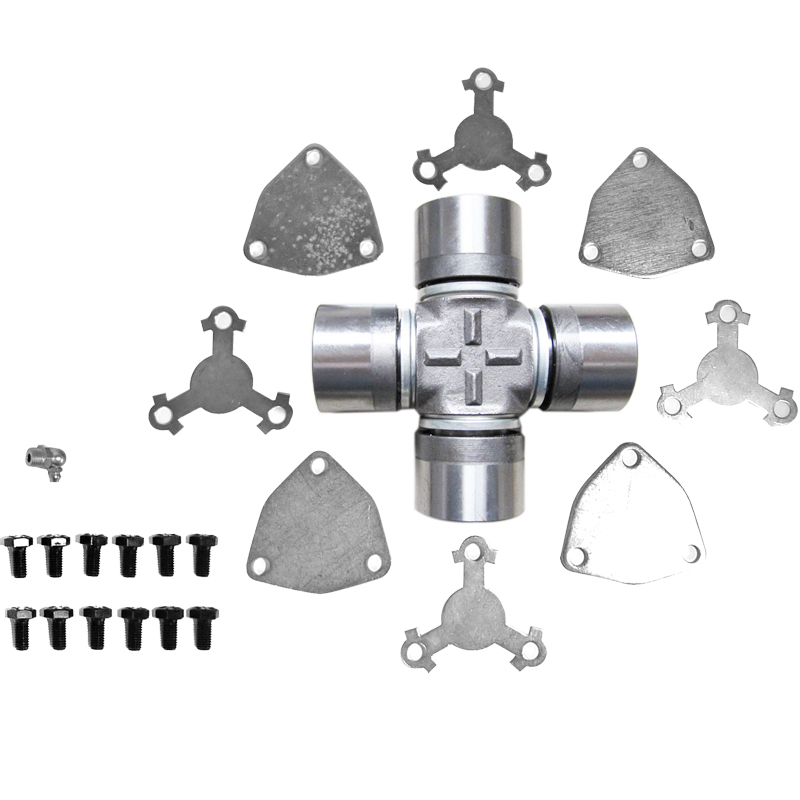

Performing detailed inspections of

Cardan joint crosses requires the use of specific tools and instruments. Here are some recommended tools and techniques for conducting inspections and detecting wear or misalignment:

Tools:

Calipers:

Use calipers to measure the dimensions of various components, such as bearing caps and trunnion journals, to check for wear.

Feeler Gauges:

Feeler gauges can help measure clearances between components, allowing you to identify excessive play or wear.

Dial Indicators:

Dial indicators are useful for measuring runout and radial play in the joint. They can help identify irregularities in the rotation of the joint.

Torque Wrench:

A torque wrench is essential for checking and adjusting the torque on fasteners to ensure proper tightness.

Alignment Tools:

Laser alignment tools or straight edges can be used to check the alignment of the shafts connected by the Cardan joint.

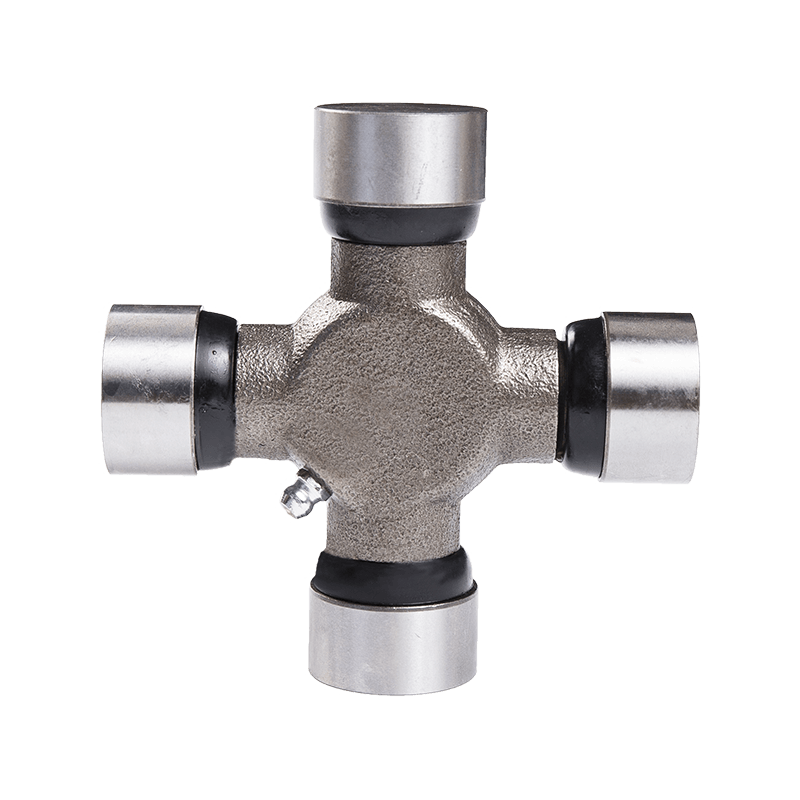

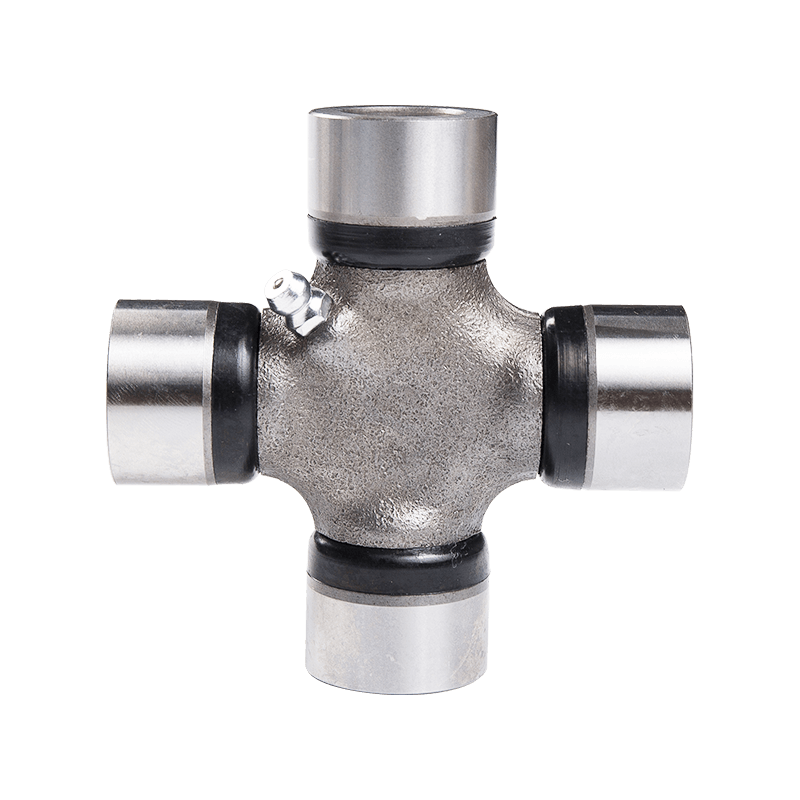

Grease Gun:

To apply lubrication during maintenance, a grease gun is necessary. It helps ensure that the joint is adequately lubricated for smooth operation.

Techniques:

Visual Inspection:

Begin with a visual inspection of the entire Cardan joint cross, looking for obvious signs of damage, rust, or misalignment.

Check for Play:

Physically check for any play or movement in the joint by attempting to move the yokes and other components. Excessive play may indicate wear.

Rotational Inspection:

Rotate the joint manually and observe for any rough spots, unusual noises, or resistance that could indicate issues with the bearings or other components.

Runout Measurement:

Use a dial indicator to measure runout (eccentricity) in the joint during rotation. Excessive runout can be a sign of misalignment or wear.

Torque Testing:

Check the torque on fasteners to ensure they are tightened to the manufacturer's specifications. Loose fasteners can lead to misalignment and premature wear.

Alignment Checks:

Use alignment tools to verify that the shafts connected by the Cardan joint are in proper alignment. Misalignment can cause uneven wear and stress on the joint.

Grease Distribution:

Observe the distribution of grease within the joint. Ensure that the grease is reaching all critical components, such as needle bearings, to prevent wear.

Ultrasonic Testing:

In some cases, ultrasonic testing can be used to detect internal defects or irregularities in the components of the Cardan joint.

Magnetic Particle Inspection:

For ferrous components, magnetic particle inspection can be employed to identify surface and near-surface defects.

Vibration Analysis:

Utilize vibration analysis tools to monitor vibrations during operation. Unusual vibration patterns can be indicative of issues such as misalignment or imbalance.

Thermal Imaging:

Infrared thermography can be used to identify potential overheating in the joint, which may be caused by friction or inadequate lubrication.

English

English Español

Español 中文简体

中文简体

Contact Us