During the installation of a

Universal Joint Cross, several methods and tools can be utilized to ensure proper alignment:

Alignment Marks:

Many U-joints and shafts have alignment marks to facilitate correct orientation during assembly. Aligning these marks ensures that the U-joint is installed in the correct phase relationship between the shafts.

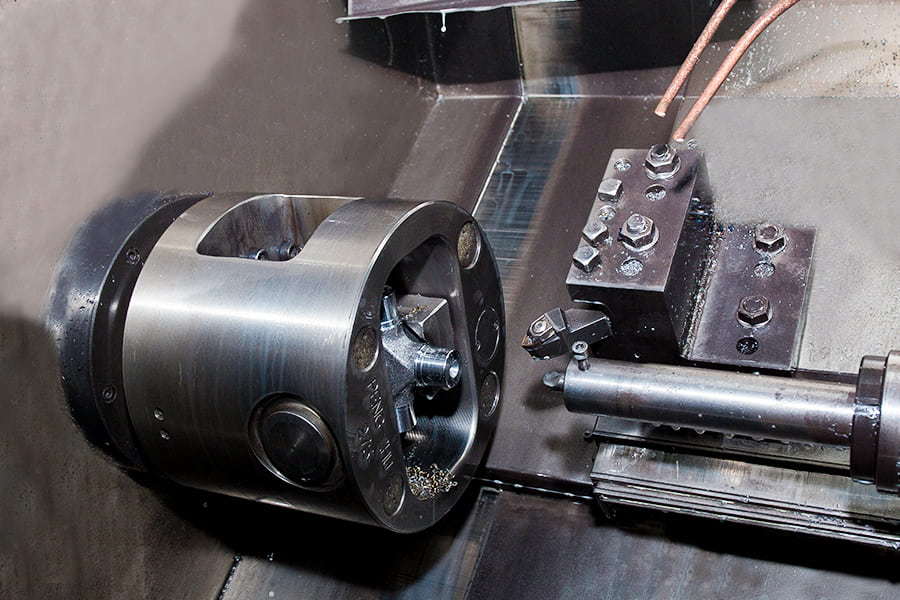

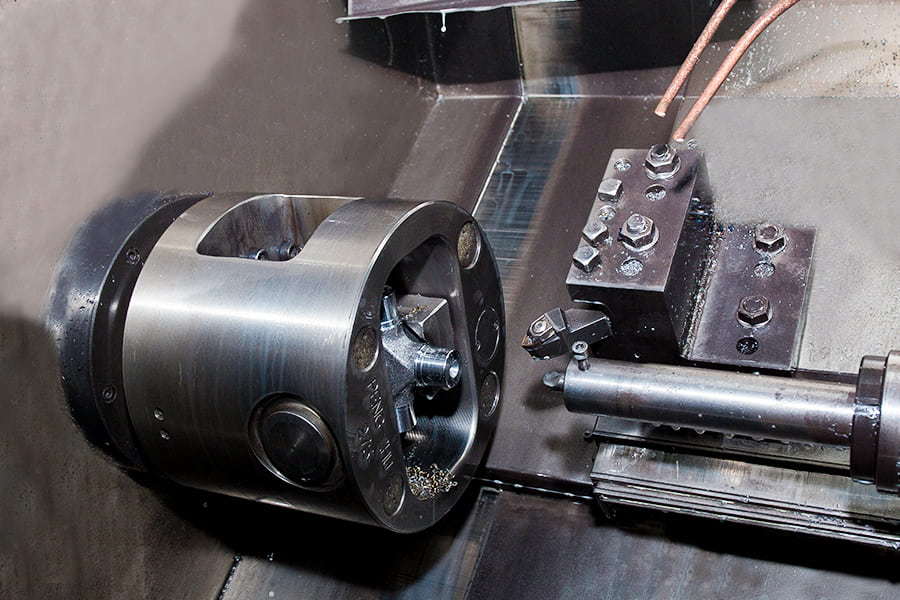

Alignment Tools:

Specialized alignment tools, such as fixtures or mandrels, can aid in aligning the U-joint and the shafts accurately during installation.

Measuring Instruments:

Calipers, micrometers, alignment lasers, or digital angle finders are used to measure and confirm the angles between the shafts. These instruments help verify that the angles meet the manufacturer's specifications for proper alignment.

Visual Inspection:

Visual inspection is crucial during installation. It involves visually confirming that the bearing caps or trunnions are aligned properly with the shafts.

Precision Jigs or Fixtures:

Special jigs or fixtures can assist in holding the components in place and ensuring accurate alignment during the installation process.

Manufacturer Guidelines:

Adhering to the manufacturer's specific instructions and recommendations for installation is vital. Manufacturer guidelines often provide detailed steps and specifications for correctly aligning the U-joint and the shafts.

Torque Wrenches:

Using torque wrenches is important to tighten the fasteners securing the

Universal Joint Cross. Proper tightening to the manufacturer's recommended torque specifications ensures the joint is securely installed without causing undue stress or misalignment.

Alignment Verification:

After installation, it's crucial to verify the alignment. This might involve rechecking alignment using tools or instruments to confirm that the U-joint and the shafts are correctly aligned.

English

English Español

Español 中文简体

中文简体

Contact Us