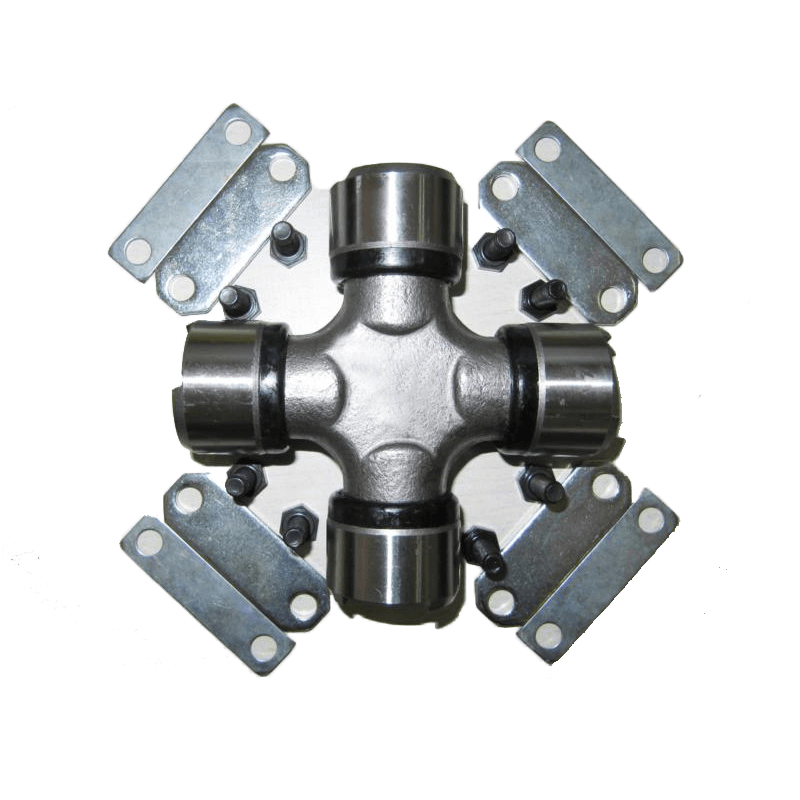

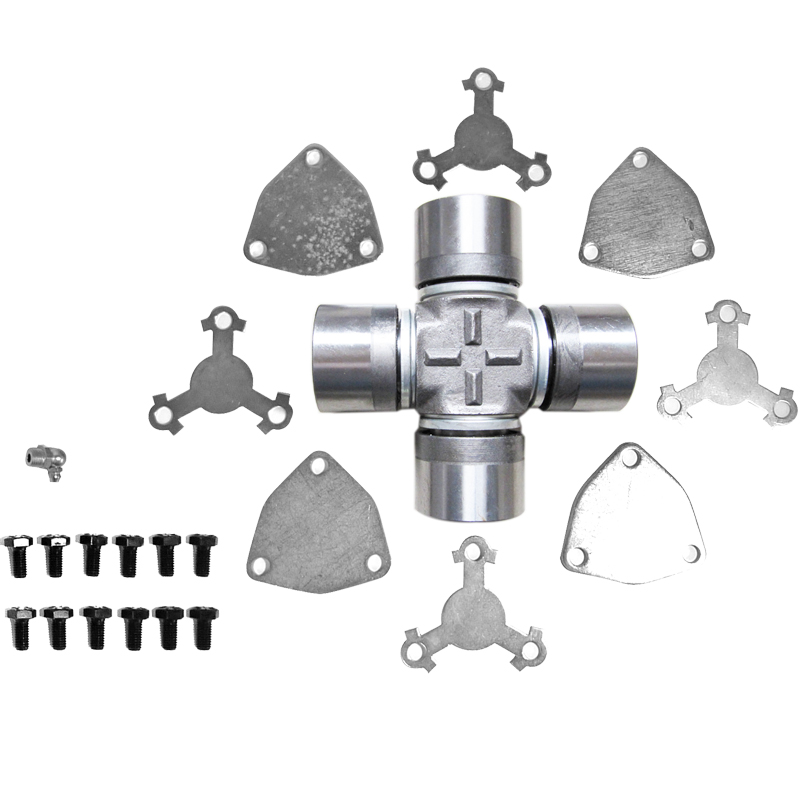

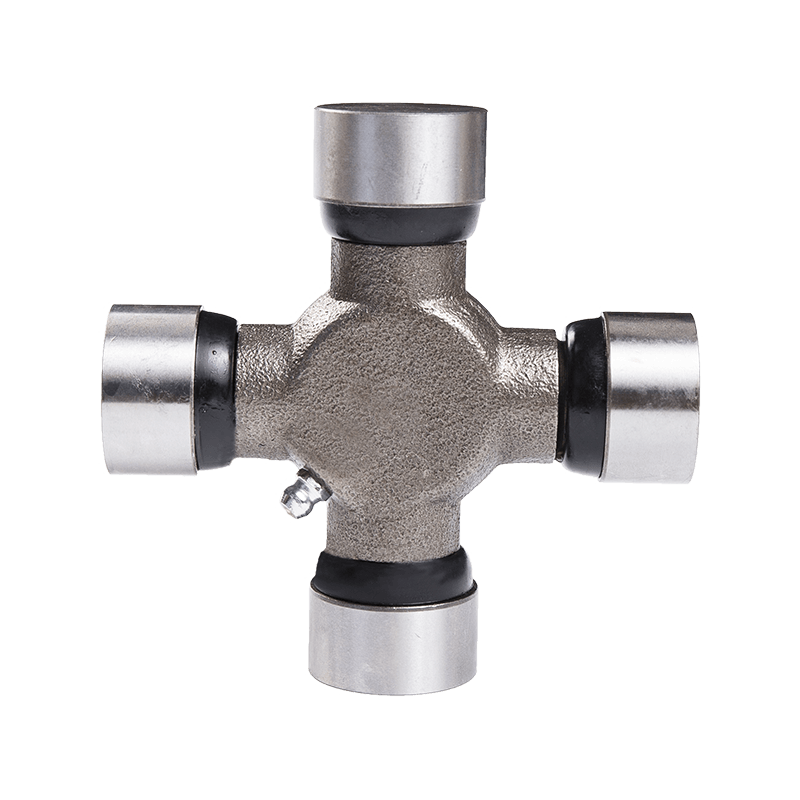

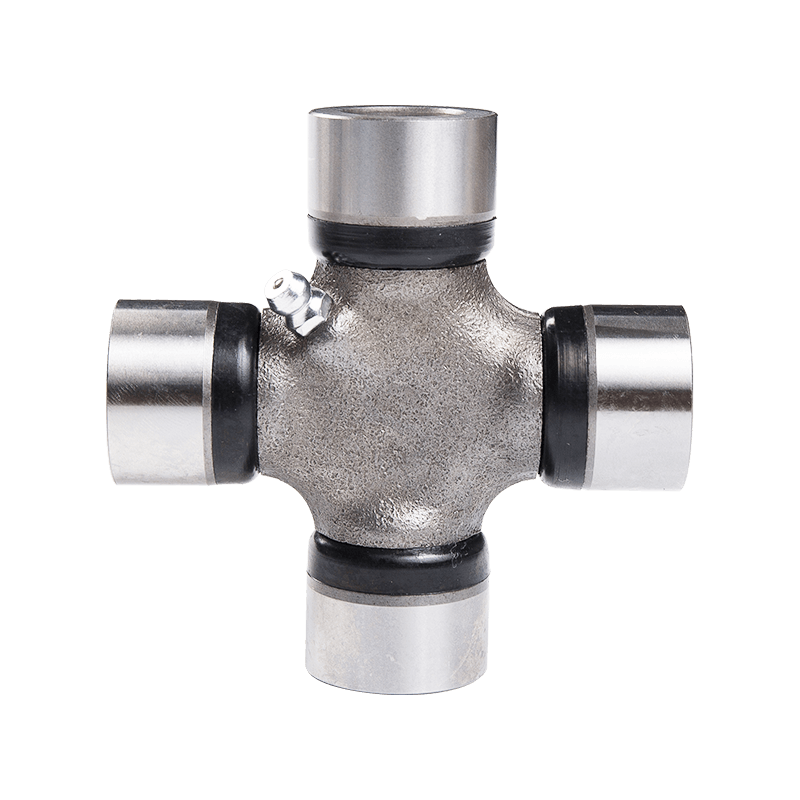

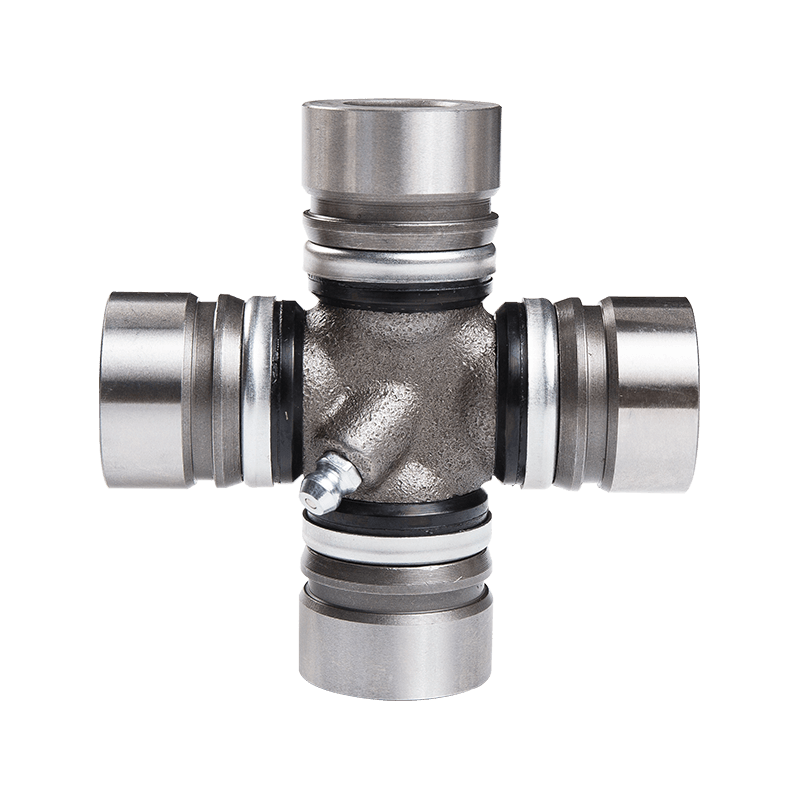

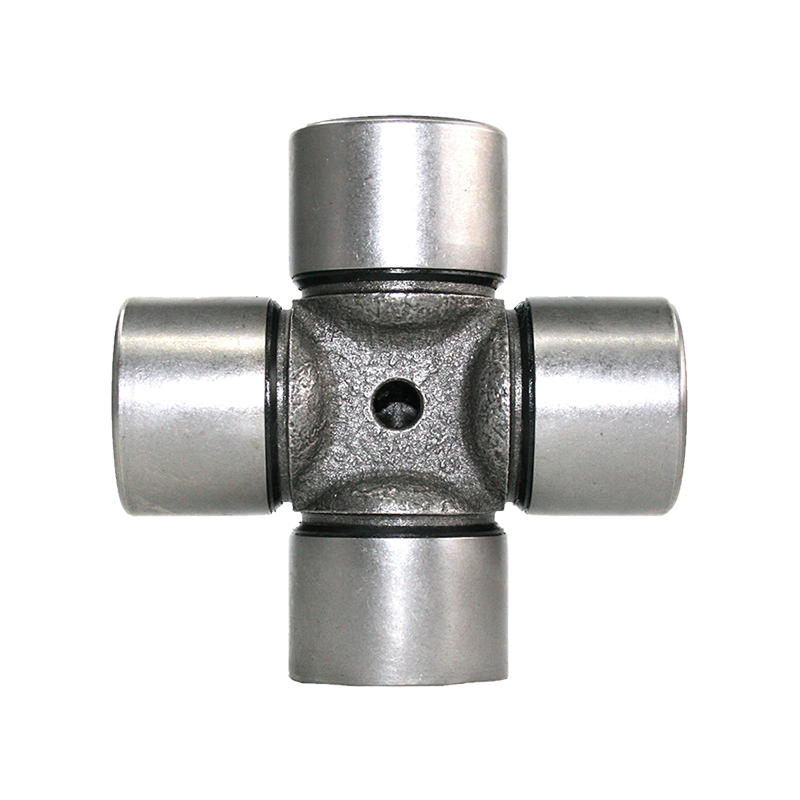

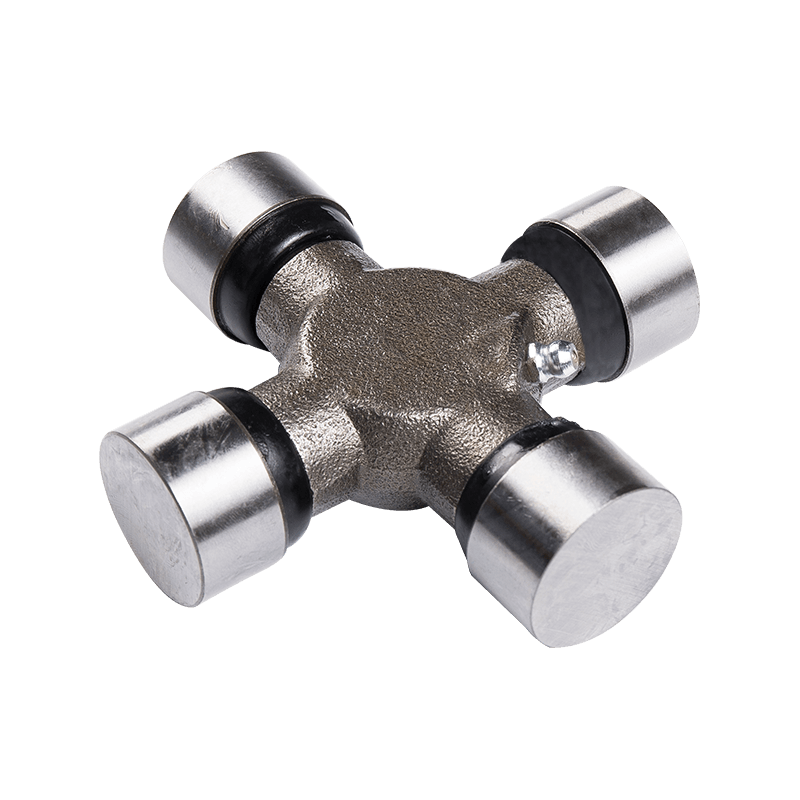

Wing bearing universal joints (U-joints) are specifically designed to excel in these demanding environments, offering unique advantages over traditional U-joints. The key to their superior performance lies in the way they manage torque and load distribution through mechanical allowances—specifically, through the strategic placement of keys in bearing blocks and the corresponding slots in the yokes. This setup creates a much more stable connection, which can be a game changer when the system is subjected to continuous or shock loads.

In typical applications, when a U-joint is exposed to vibration or fluctuating loads, stress concentrations can lead to premature wear and failure. However, with wing bearing U-joints, the load distribution is much more even due to the added mechanical allowances. This results in less localized wear and a greater capacity to absorb shock loads without compromising structural integrity. The bearing blocks in wing bearing designs help absorb and dissipate vibrations more effectively, meaning these U-joints are far less likely to suffer from fatigue damage under repetitive stress cycles. This makes them ideal for environments where heavy-duty operation and shock-loading conditions are common—like in heavy machinery, off-road vehicles, and industrial applications.

Another area where wing bearing U-joints shine is in their ability to handle cyclic loading. Cyclic loads are not just about repeated pressure but also about the gradual fatigue that can build over time, potentially leading to catastrophic failure. The wing bearing’s design addresses this by ensuring that torque is transmitted evenly across all components, which reduces the frequency and severity of high-impact stresses. The wing bearing’s ability to distribute loads more effectively helps in extending the service life of the joint, even when exposed to constant cycles of tension and compression.

The material choices for wing bearing U-joints further enhance their durability. High-quality alloys and precision manufacturing ensure that the parts hold up well even in the most extreme operational conditions. When compared to traditional U-joints, which can sometimes fail under extreme vibration due to concentrated stresses, wing bearing U-joints stand out in their ability to maintain stability and minimize wear. By withstanding higher vibration amplitudes and more dynamic loading, these U-joints contribute to reduced maintenance needs and longer overall equipment lifespans, which ultimately translates to cost savings over time.

Wing bearing U-joints offer an excellent solution for applications prone to extreme vibration and cyclic loading. They not only improve performance but also extend the operational life of the entire system, making them an ideal choice for industries requiring heavy-duty performance and reliability. Whether in high-shock load conditions or environments with continuous vibration, these U-joints outperform traditional designs, providing the durability and longevity that today’s demanding applications require.

English

English Español

Español 中文简体

中文简体

Contact Us