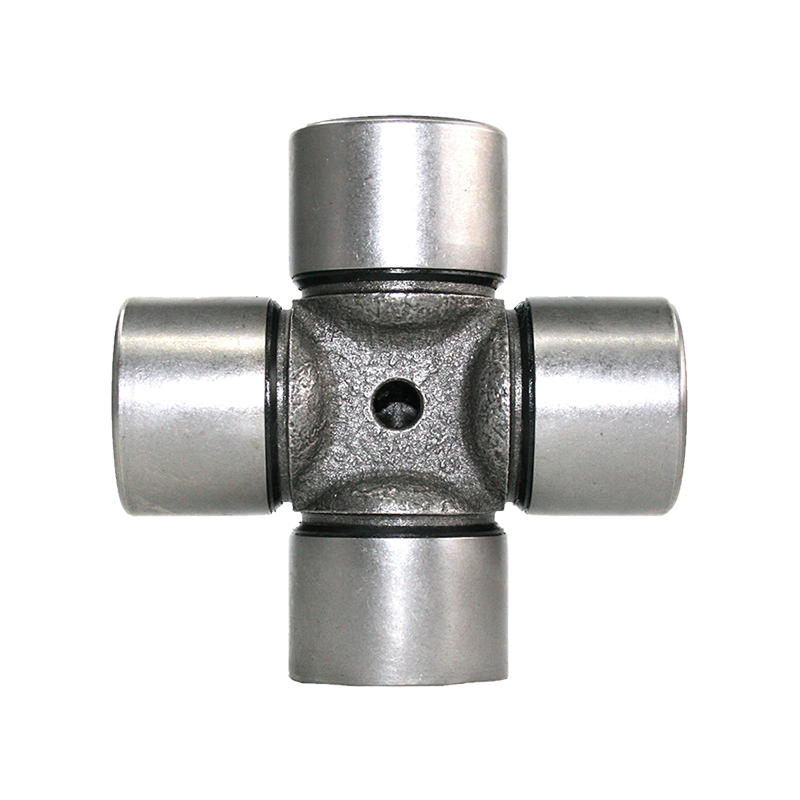

In the intricate world of mechanical engineering, the quest for optimal performance while maintaining cost-efficiency is perpetual. One crucial component that often embodies this delicate balance is the universal joint, a fundamental element in transmitting rotational motion between shafts. Amidst the array of designs available, the universal joint with slotted bearings emerges as a stalwart contender, renowned for its robustness in heavy-duty applications.

Understanding the Universal Joint with Slotted Bearings

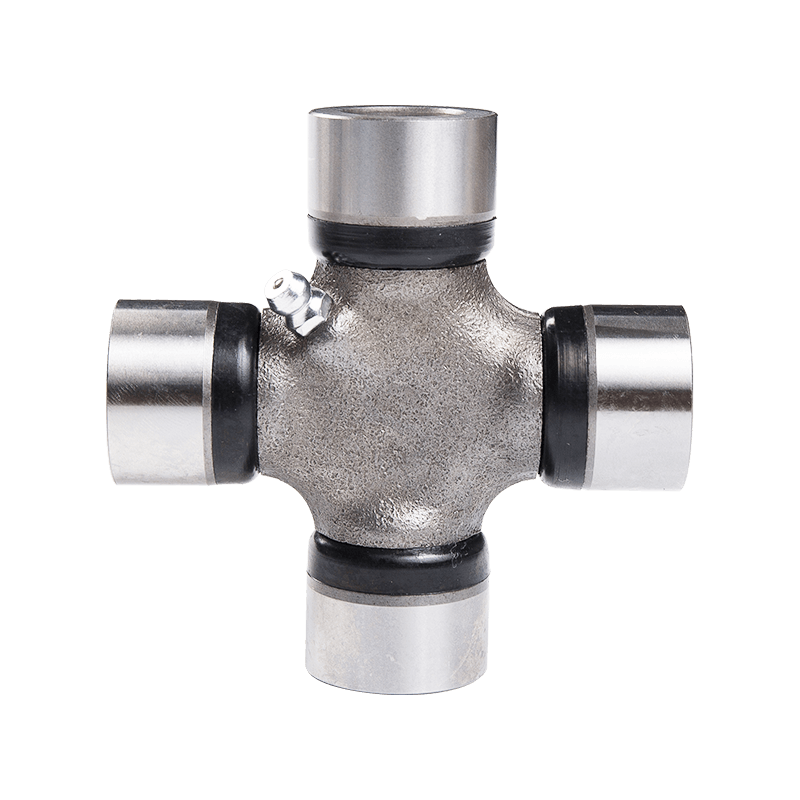

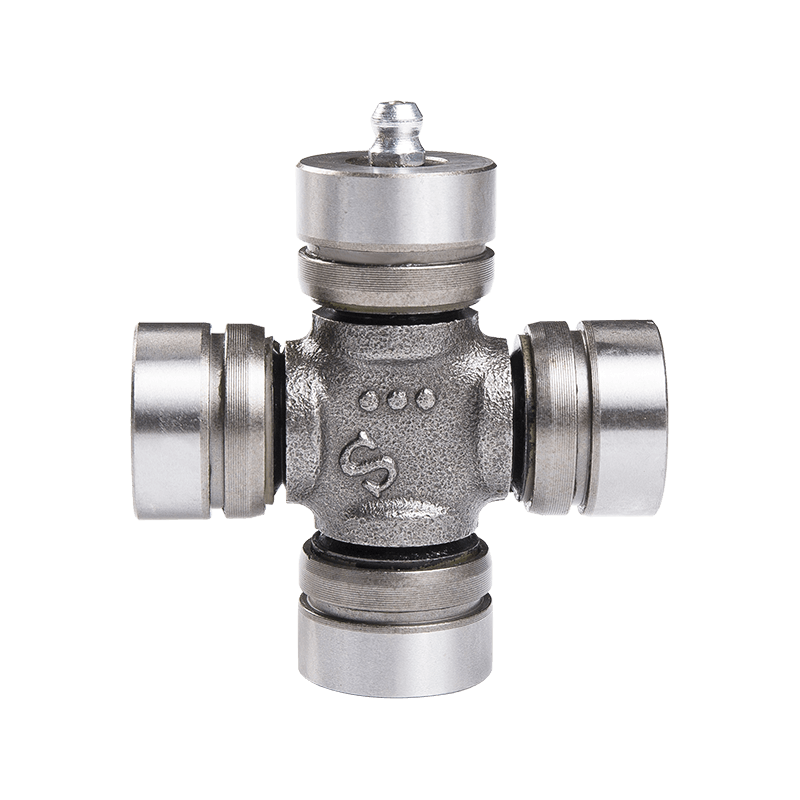

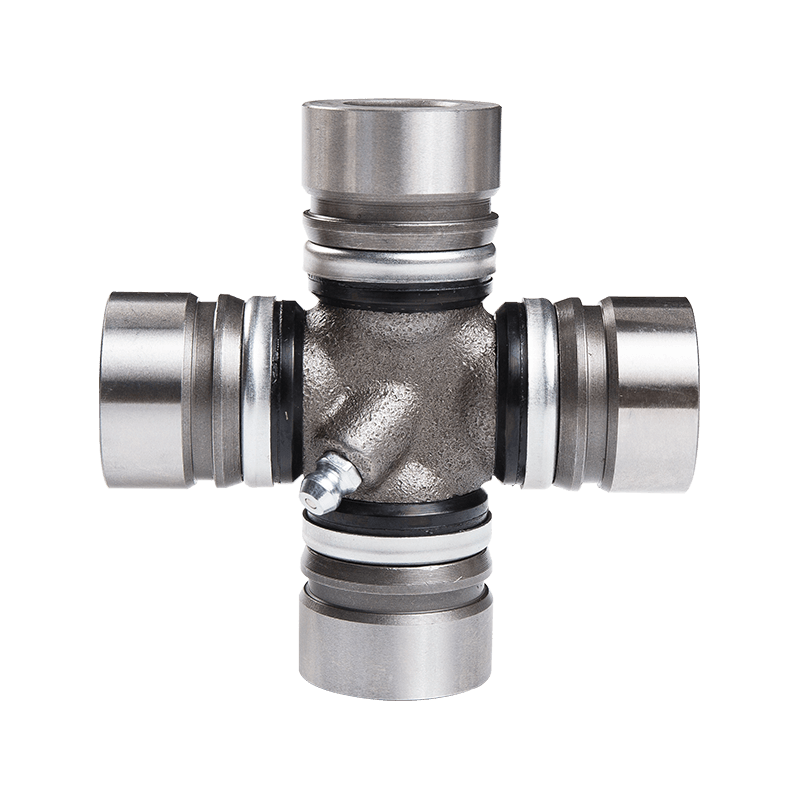

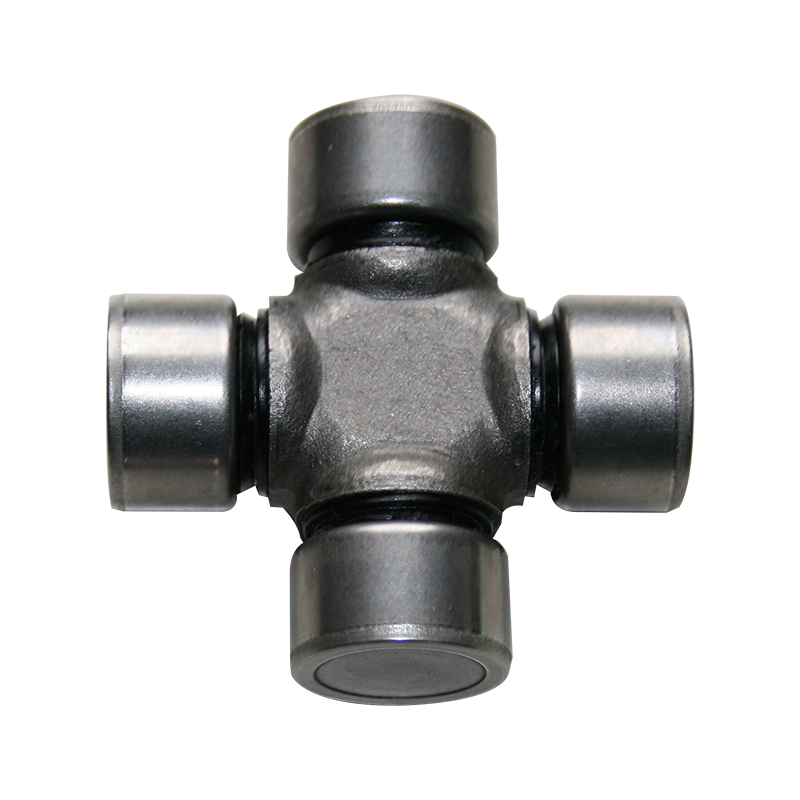

A universal joint with slotted bearings epitomizes precision engineering. Unlike its conventional counterparts, this joint features slotted bearings with grooves at the cup's bottom, providing a secure fit for a plate, which is then bolted in place. Such meticulous design isn't just for aesthetics; it's a testament to the demands of heavy-duty applications, particularly prevalent in Japanese trucks.

Cost Considerations: Beyond the Initial Investment

At first glance, the universal joint with slotted bearings may appear slightly pricier than simpler designs. This difference in cost can be attributed to the intricate manufacturing processes required to produce the slotted bearings and grooves. However, assessing the true cost involves delving deeper into the lifecycle of these components.

The Value Proposition: Longevity and Reliability

While the initial investment in a universal joint with slotted bearings might be marginally higher, its enduring value becomes apparent over time. In heavy-duty applications where reliability is paramount, these joints shine. Their robust construction, fortified by the slotted bearings, ensures resilience against wear and tear, minimizing downtime and maintenance costs.

Performance Metrics: Efficiency and Operational Savings

The cost analysis extends beyond mere dollars and cents; it encompasses performance metrics and operational savings. Universal joints with slotted bearings excel in transmitting torque efficiently, even under extreme loads and harsh conditions. Their ability to withstand rigorous environments translates into enhanced operational efficiency and prolonged service intervals, mitigating overall lifecycle costs.

Comparative Analysis: Weighing the Options

To truly grasp the cost dynamics, it's imperative to compare universal joint with slotted bearings to their alternatives. While simpler designs may boast lower upfront costs, they often pale in comparison regarding durability and performance. When longevity, reliability, and operational efficiency are factored in, the perceived cost difference diminishes, if not reverses.

English

English Español

Español 中文简体

中文简体

Contact Us